Oil & Gas

Maintaining a precise record of the location and condition of your assets is crucial to maximizing efficiency, sustainability, and regulatory compliance. Laser scanning makes it possible to capture every detail accurately in minutes and put all the information you need at your fingertips.

Common Challenges

Shutdowns

Turnaround for repair or maintenance can be an issue when thousands of barrels of oil are waiting to be processed.

Complex Structure

Congested pipe runs create a complicated network that leaves little room for error when designing and installing new equipment.

Regulatory Compliance

Increasingly stringent environmental and safety regulations require plants to quickly retrofit to remain compliant and provide accurate reporting.

benefits of laser scanning reality capture

Comprehensive

Documentation

With 3D laser scanning you have all the data at your fingertips, allowing you to properly manage repairs, coordinate maintenance plans and generate reports.

Powerful

Insights

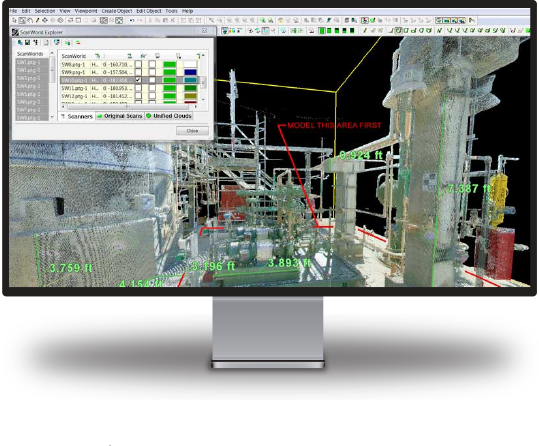

With our powerful software solutions 3D laser scanning data can be leveraged to its fullest potential, allowing for the software to identify clashes, surface issues, and even tank analysis.

Safeguarding

Personnel

The ability to capture 3D measurements safely from the ground with a single operator keeps workers out of harm's way and allows for digital remote management of your entire operation, keeping plant visits to a minimum.

discover insights

Laser Scanning Solutions

Whether your data capture priorities are distance, speed, accuracy, flexibility, ease of use, autonomous operation, or all of the above, Leica Geosystems provides industry-leading solutions that simplify your digital transformation.

Software Solutions

The security, accessibility and usability of your laser scanning reality capture data is crucial to maximizing operational efficiency and obtaining the best return on your investment. Leica Geosystems software leads the industry for transforming vast amounts of digital data into intuitive yet powerful information assets.

Seamless Integration

Our solutions are compatible with the most popular third-party software, making it easy to integrate reality capture into your existing workflows.