...they’re used to handling time-sensitive requests, but this was the tightest deadline the firm had ever encountered.

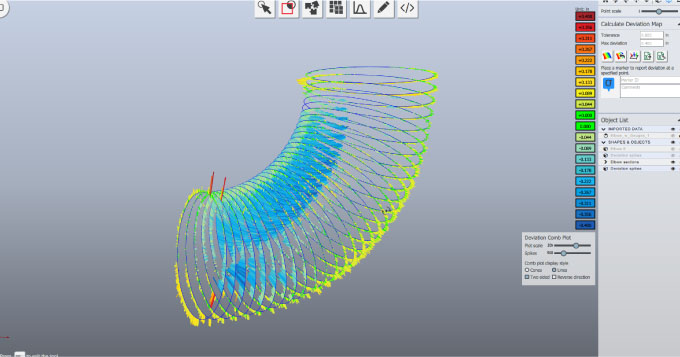

At one o’clock on a Friday afternoon, Element6 received a call. A client had a critical need for precise measurements for a fitness-for-purpose evaluation. Would Element6 be able to come in that day, get the information, and provide deliverables that evening if needed?

The Georgetown, Ontario, Canada-based boutique engineering consulting firm has built a reputation providing fast and cost-effective service to clients in the specialty chemicals industry, so they’re used to handling time-sensitive requests, but this was the tightest deadline the firm had ever encountered. Still, Rob Jickling, Element6’s Consulting Principal, didn’t hesitate. He told his team to get ready.

At 3:00 p.m., the client confirmed they needed Element6 on the job; an hour later, Element6 was onsite. Greg Schneider, regional manager of Industrial Plant Solutions Canada and Northern US for Leica Geosystems, part of Hexagon, also lent his support on the project. By 1:00 a.m., just 12 hours after the initial call, Element6 delivered the requested data to the client.

Traditionally, meeting this type of request would have taken weeks and required a significant amount of labor. But Element6 relies on a lean, fully digital approach to plant engineering and design that makes all the difference when time is of the essence.

Element6 uses an all-digital approach called Virtual Plant Design (VPD) to deliver low-cost, high-quality, high-speed service.

Laser Scanning Innovation Enables Speed and Quality

To deliver low-cost, high-quality, high-speed service, the team uses an all-digital approach they call Virtual Plant Design (VPD).

Element6 works fast with one goal in mind: client success. “Most people in the engineering business think about engineering,” says Jickling. “We focus exclusively on getting that end result for our clients. They might want to make money, save money or reduce risk. Maybe they want to improve productivity or introduce new products, or maybe they’ve got health and safety issues they want resolved. Whatever their objective, that is our goal.”

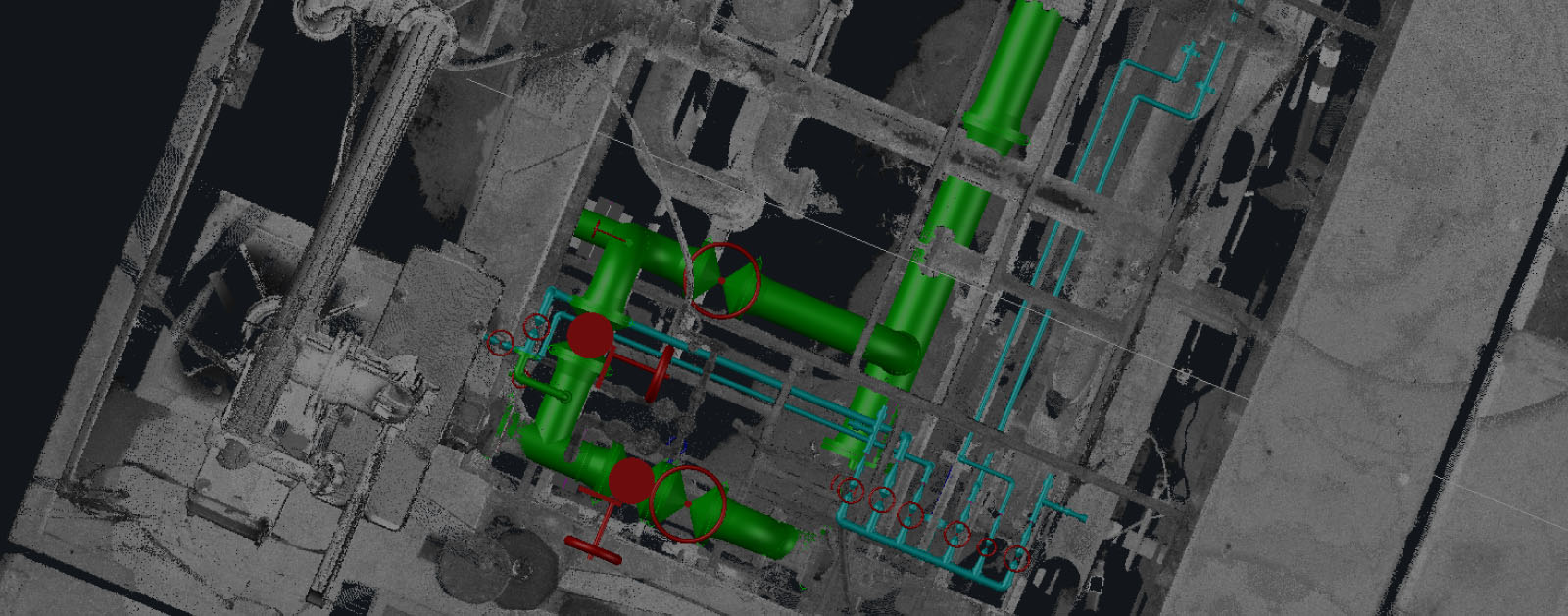

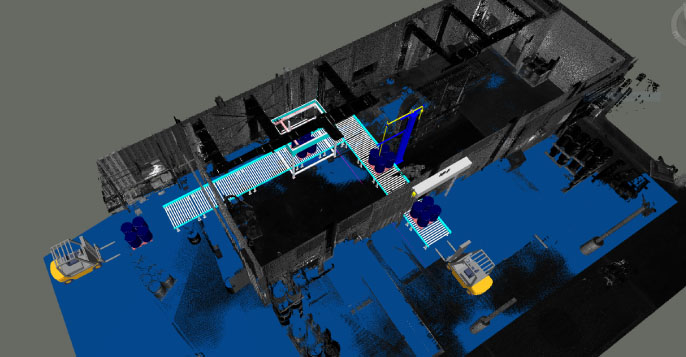

To deliver low-cost, high-quality, high-speed service, the team uses an all-digital approach they call Virtual Plant Design (VPD). They begin with a digital point cloud of the as-built conditions, captured with high-accuracy laser scanning, which helps them quickly find the solution to issues regarding plant renovations, process optimization, new equipment installations, or whatever challenges their clients face.

Using their lean workflow, the company works so fast that they sometimes have to wait for their clients to catch up and provide feedback on the proposed solution. Clients who are used to traditional blueprints and CAD modeling work are stunned by how quickly Element6 can provide high-quality engineering consulting, performing work in weeks or even days that would traditionally have taken months, with deliverables that are much more comprehensive and informative.

This is all made possible by Element6’s laser scanning technology. While some engineering consulting firms prefer to rent their technology on an as-needed basis, Element6 has strategically invested in several scanners, including a professional-grade Leica ScanStation P30, a Leica BLK360 imaging laser scanner, and, most recently, two Leica RTC360 portable, automated, high-speed laser scanners that capture complete scans with high-dynamic-range (HDR) imagery in less than two minutes and automatically pre-register the scans in the field. The company also handles its own point cloud processing using Leica Cyclone software, along with JetStream and CloudWorx for easy CAD integration, and TruView for easy accessibility.

Purchasing the technology instead of renting it has enabled Element6 to become experts in capturing and using point clouds—which, in turn, allows the company to offer unexpected benefits to its clients. For example, in a traditional approach, an initial consultation would be followed by a proposal and then a return to the site to capture as-built conditions before work could begin. In contrast, Element6 often brings one of its RTC360 laser scanners to the first meeting and captures 10 or 20 scans onsite in a matter of minutes. The scanning and registration are done so quickly that the firm is often able to begin work on the project immediately, significantly reducing turnaround time.

The company’s lean workflow is so fast that they sometimes have to wait for their clients to catch up and provide feedback on a proposed solution.

Laser Scanning Integrity Allows for an Innovative Business Model

We’re not incentivized to spend more man hours doing things,” Jickling says. “We’re incentivized to get the project done as quickly and productively as possible.

When Rob Jickling founded Element6, he wanted to create a business centered around accountability and a results-oriented approach. Element6 spends time up front identifying exactly what the client needs and then sets a price based on the service that will be required—not the amount of time required to complete the work. This fixed price model radically sets Element6 apart from other engineering consulting firms. “We’re not incentivized to spend more man hours doing things,” Jickling says. “We’re incentivized to get the project done as quickly and productively as possible.”

This business model constantly challenges the company to find new ways to be faster, more innovative, and more focused on meeting the client’s needs. When making technology decisions, Element6 carefully considers not just the capabilities of the hardware, but the complete field-to-finish workflow, the support provided by the manufacturer, and the track record of innovation. “Leica Geosystems has industry-leading hardware, but it also has a fully integrated workflow and a commitment to reliable service and continued innovation,” Jickling says. “We rely on Leica Geosystems as a partner that will help us stay on the leading edge.”

This type of partnership builds confidence into the company’s operations and enables Element6 to provide clients with outstanding service. “We’ve been in this business a long time, so we have the knowledge and understanding not just of engineering but of our clients’ businesses and their business needs,” Jickling says. “That understanding, combined with our efficiency and productivity because of technology, allows us to provide our clients with significant advantages in terms of both pricing and value. Our clients know they can count on us to exceed their expectations, and that’s a win for everyone.”

Having an accurate and up-to-date 3D point cloud as-built gives plants instant access to measurement data and enables them to work with consultants remotely to identify solutions and avoid downtime.

Point Clouds Provide Real-Time Intelligence

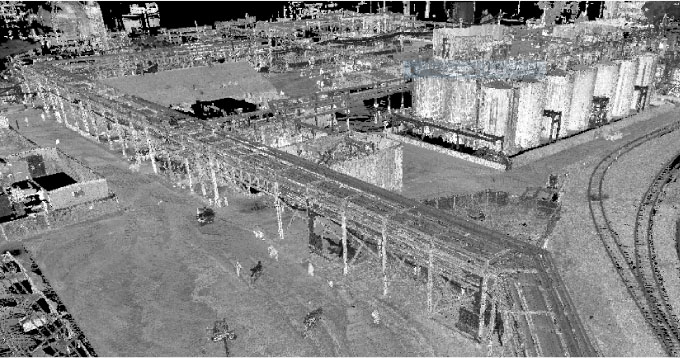

Jickling envisions a future in which every plant has an accurate 3D point cloud as-built.

The days of blueprints and spending hours measuring as-builts are over. With laser scanning, Element6 produces high-detail virtual point clouds of engineering plants that can be quickly referenced with something as easy as a few clicks on a computer or taps on a mobile device. No more costly delays due to flawed measurements—it’s all there in the point cloud.

Jickling envisions a future in which every plant has an accurate 3D point cloud as-built. As technology develops, live data could be fed into the point cloud to keep the as-built current, with constantly updated information regarding temperature, pressure, and other variables within the plant. With a complete and up-to-date point cloud, clients wouldn’t need last-minute scans of elbows on a Friday afternoon; they could just pull up the already-existing data. Instead of waiting for engineers to travel to their site, they could work with consultants remotely to identify solutions and avoid downtime.

“Why create a bunch of blueprints?” Jickling says. “The model is here, all the information is here—why would anyone want to spend money creating paper? We’re working with plant owners and EPC contractors to up their game using technology, which reduces costs and significantly improves outcomes.”

With laser scanning, Element6 produces high-detail virtual point clouds of engineering plants that can be quickly referenced with something as easy as a few clicks on a computer or taps on a mobile device.

Learn more about Element6, the Leica 3D Laser Scanning solutions, or contact us for a consultation on your project needs.

HIGH-VALUE DELIVERABLES

- High resolution registered point clouds

- Leica TruViews

- 3D CAD models

BENEFITS

Increased Safety

All data captured from ground level

Fast Data Collection

All data captured in a single day with a two-person crew vs. two weeks for a traditional documentation process provided a cost savings of 68%

Comprehensive Data Capture

Accurate, comprehensive data enabled virtual clash checks and prevented rework costs

Better Project Visualization

TruViews and 3D models enable stakeholders to make better decisions