When a compressor station owner in the Marcellus Shale natural gas formation was tasked with starting up a three-engine temporary station in just three weeks, the company readily agreed. Accomplishing the goal, however, appeared to be a daunting task. Such stations typically require at least six weeks to install and bring online, and missing the deadline would bring steep penalties.

Location

Williamsport, PA

The station owner turned to Appellation Pre-Fab, a general contractor and industrial piping fabricator located in the Marcellus Shale region near Williamsport, Pa. Focusing on the oil and gas industry, Appellation Pre-Fab creates structures for meter and compressor stations as well as launchers and receivers.

Given that they had committed to slashing project time by 50 percent, Appellation Pre-Fab Lead Design Engineer Rob Schnars had his work cut out for him. He knew, however, that his company’s investment in a Leica ScanStation C10 in the fall of 2015 would enable him to compress the schedule and reach the finish line on time. The Leica ScanStation C10 scans the environment from up to 300 meters away and gathers comprehensive details of a panorama by sweeping a laser beam over it and determining the distance between the scanner and structures it identifies. It collects precise measurements of the scanned surfaces. The result is a set of data points in a three-dimensional coordinate system, or point cloud, which represents the outer surface of the scanned objects.

Using the Leica ScanStation to capture accurate, comprehensive data enabled the team to verify all measurements before they proceeded with fabrication processes, thereby avoiding rework.

Rapid Documentation Enables Fast Turnaround

In this way, Schnars, working alone, completed in two days what would normally take 10 days for a two-person crew.

Acting as the mechanical contractor for the accelerated compressor station project, Appellation Pre-Fab’s goal was to have the three-engine temporary compressor station up and running as quickly as possible. At the beginning of the first week, as soon as the pipe-rack skids were set and the last of the three engines was being set, Schnars began scanning. That day, along with nine high-resolution scans, he also took photographs. Each setup, scan and set of pictures took about 30 minutes.

At the end of the second week, almost all the remaining equipment had been set up, including dehydration towers, heaters and horizontal filter separators. At that point, Schnars took 10 more scans. Despite a light snow that had coated the structures, the scans came out perfectly. In this way, Schnars, working alone, completed in two days what would normally take 10 days for a two-person crew. “With the Leica ScanStation, you don’t have to drag a tape around a job site, or wonder if your measurements are square,” said Schnars. “In fact, there’s no more physical measuring, period.”

Easy Workflows Streamline Project Completion

After we have a scan, a user can go back in and pull dimensions as needed. This is an incredibly valuable, time-saving tool, said Schnars.

Because of the fast turnaround required on the project, Appellation Pre-Fab’s staff created sketches and measurements concurrently. Once the design department caught up on their drawings, they used the laser scans to verify all measurements before they proceeded too far with the fabrication processes or began shipping the spools. “After we have a scan, a user can go back in and pull dimensions as needed. This is an incredibly valuable, time-saving tool,” said Schnars. “There’s no more need to return to a jobsite to confirm measurements or take missed measurements.”

If the designers discovered a spool would not fit based on the measurements, they made corrections immediately, avoiding costly shipping and rework.

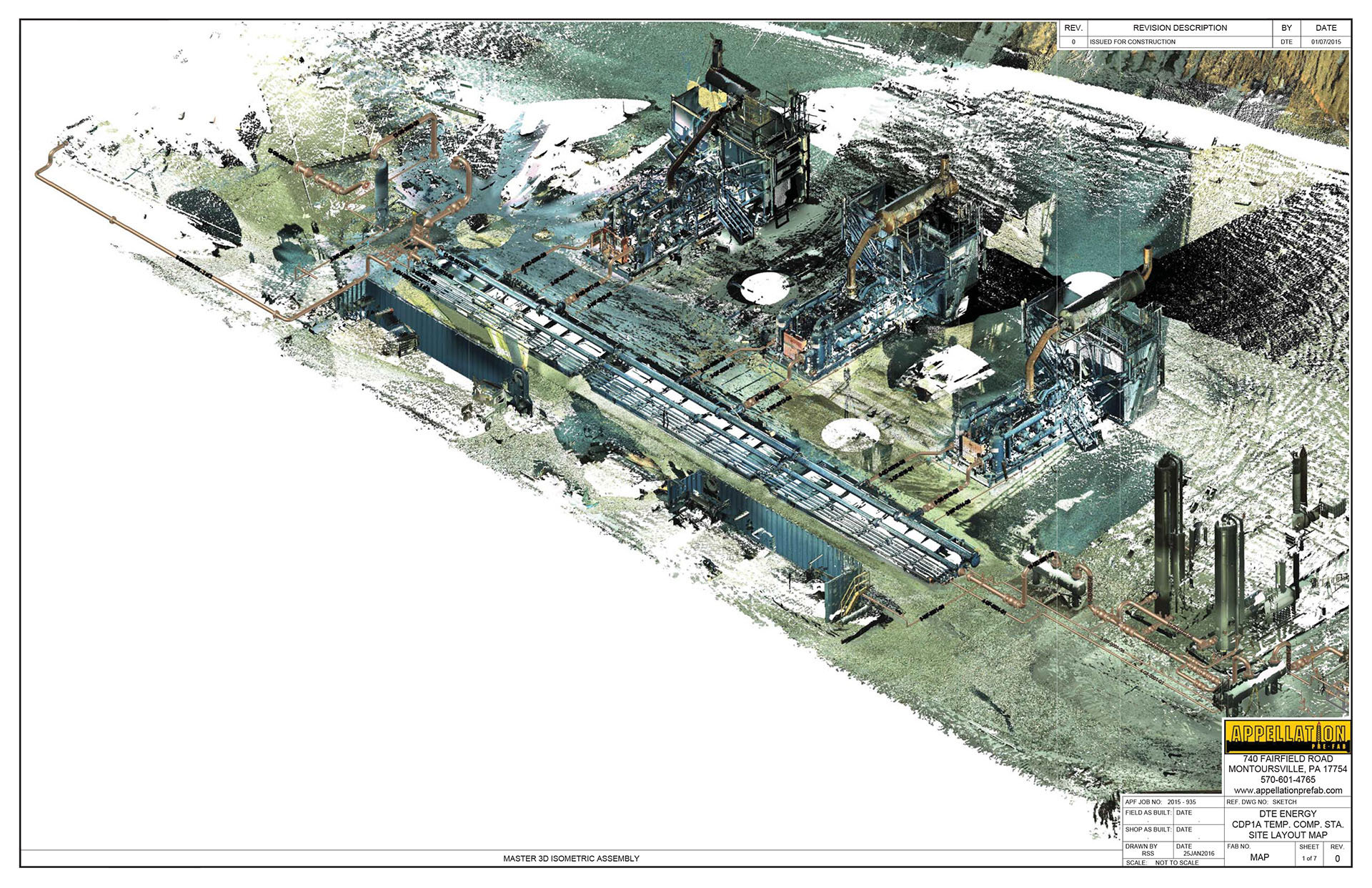

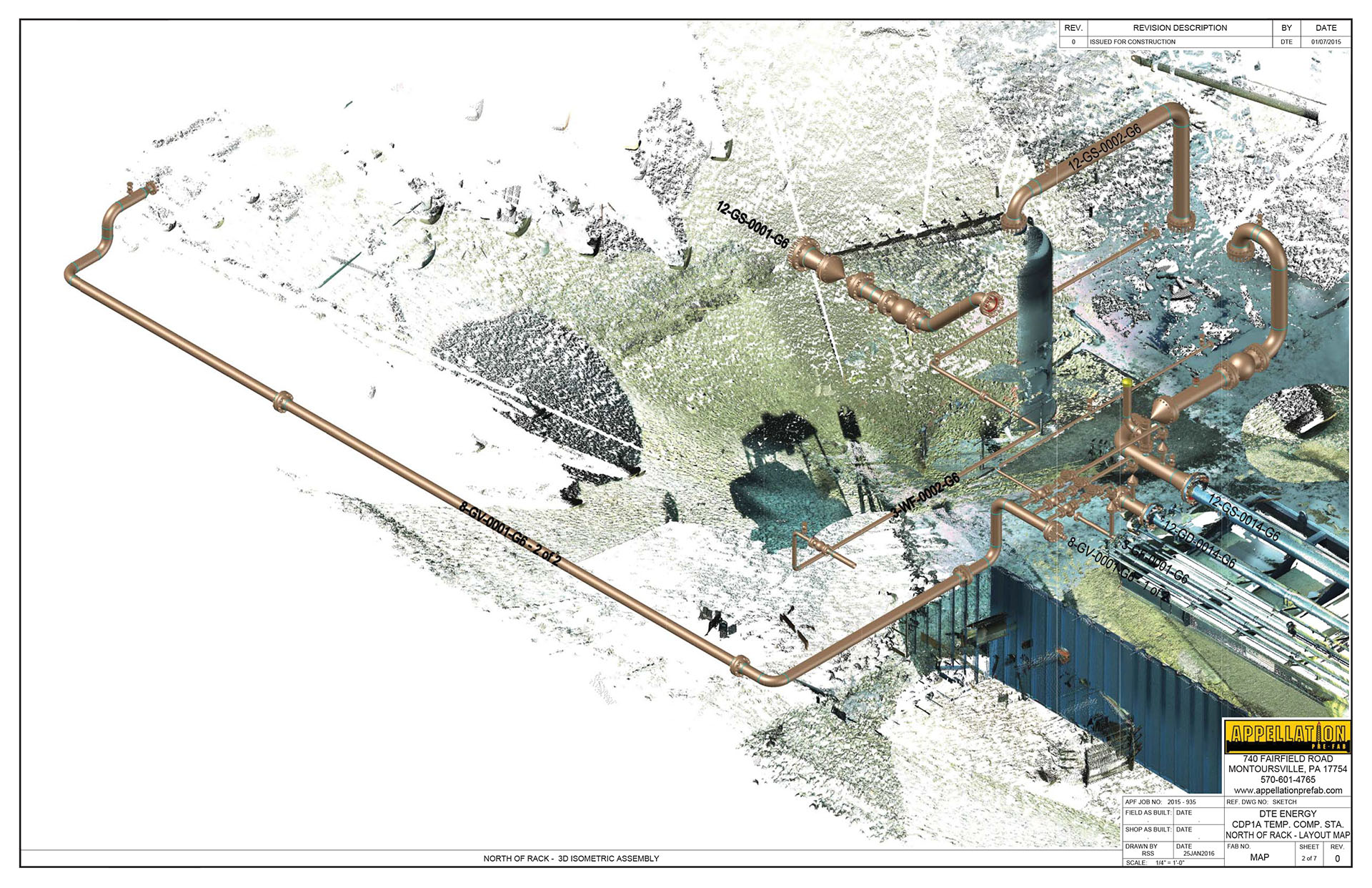

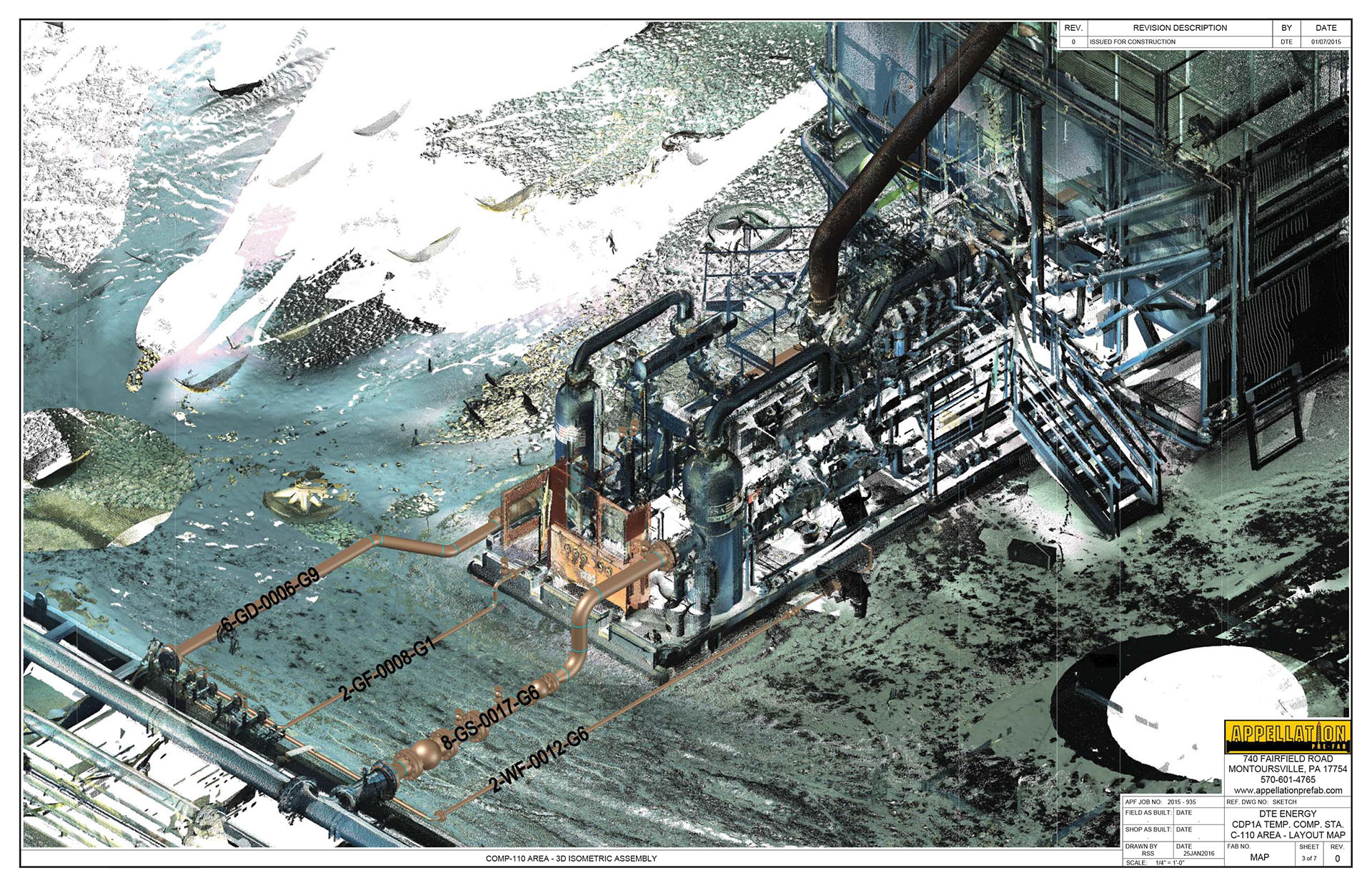

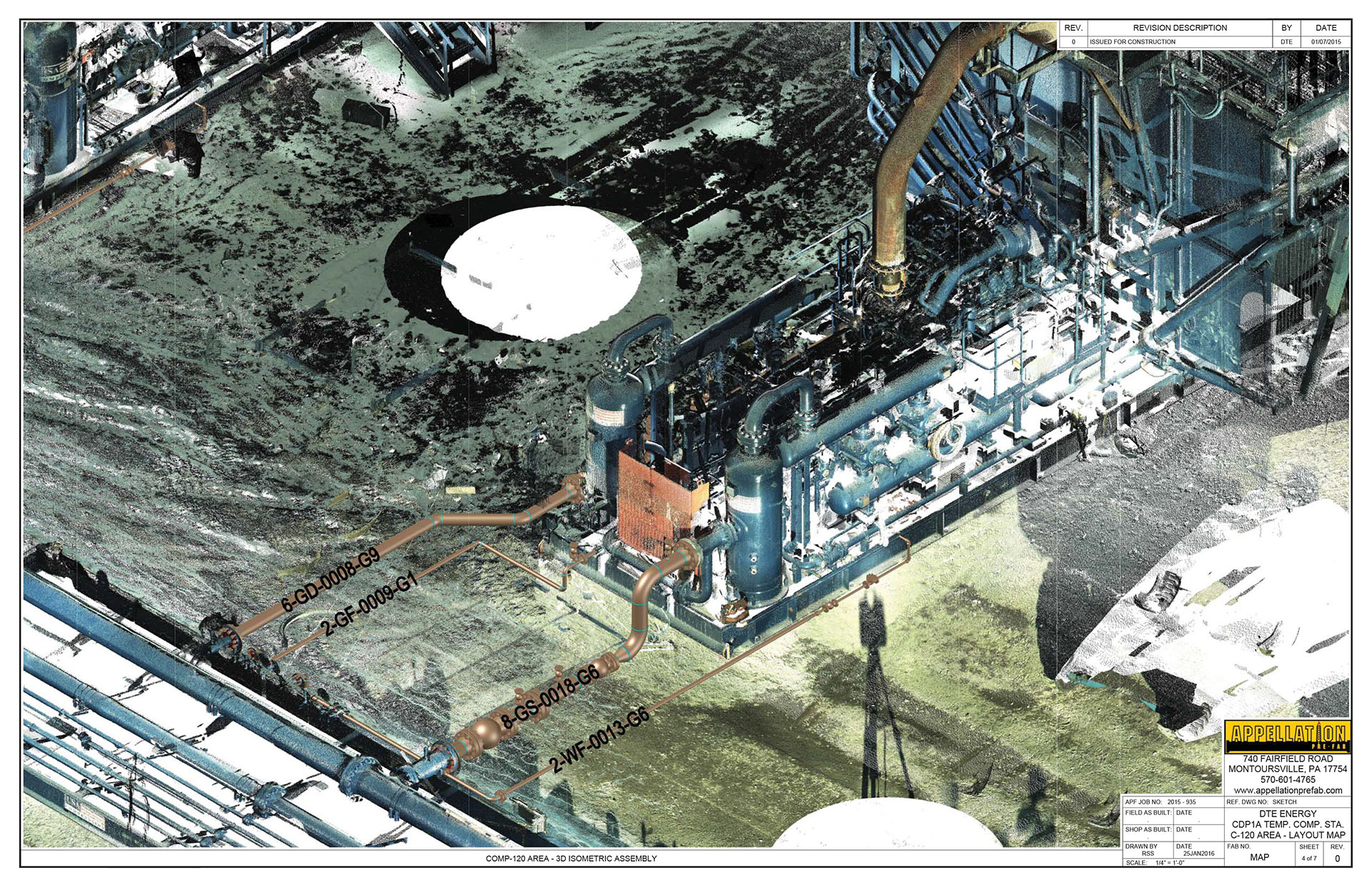

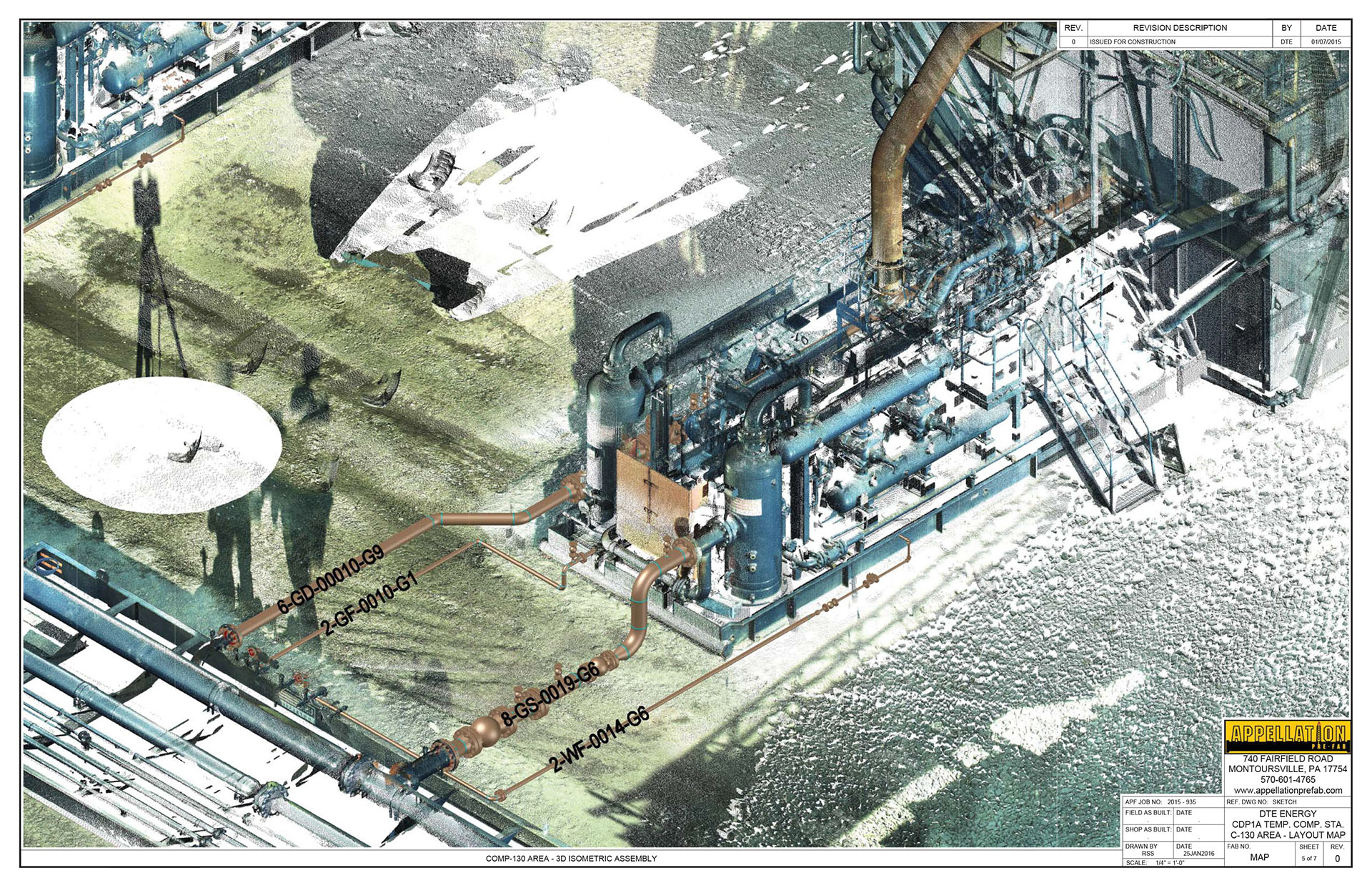

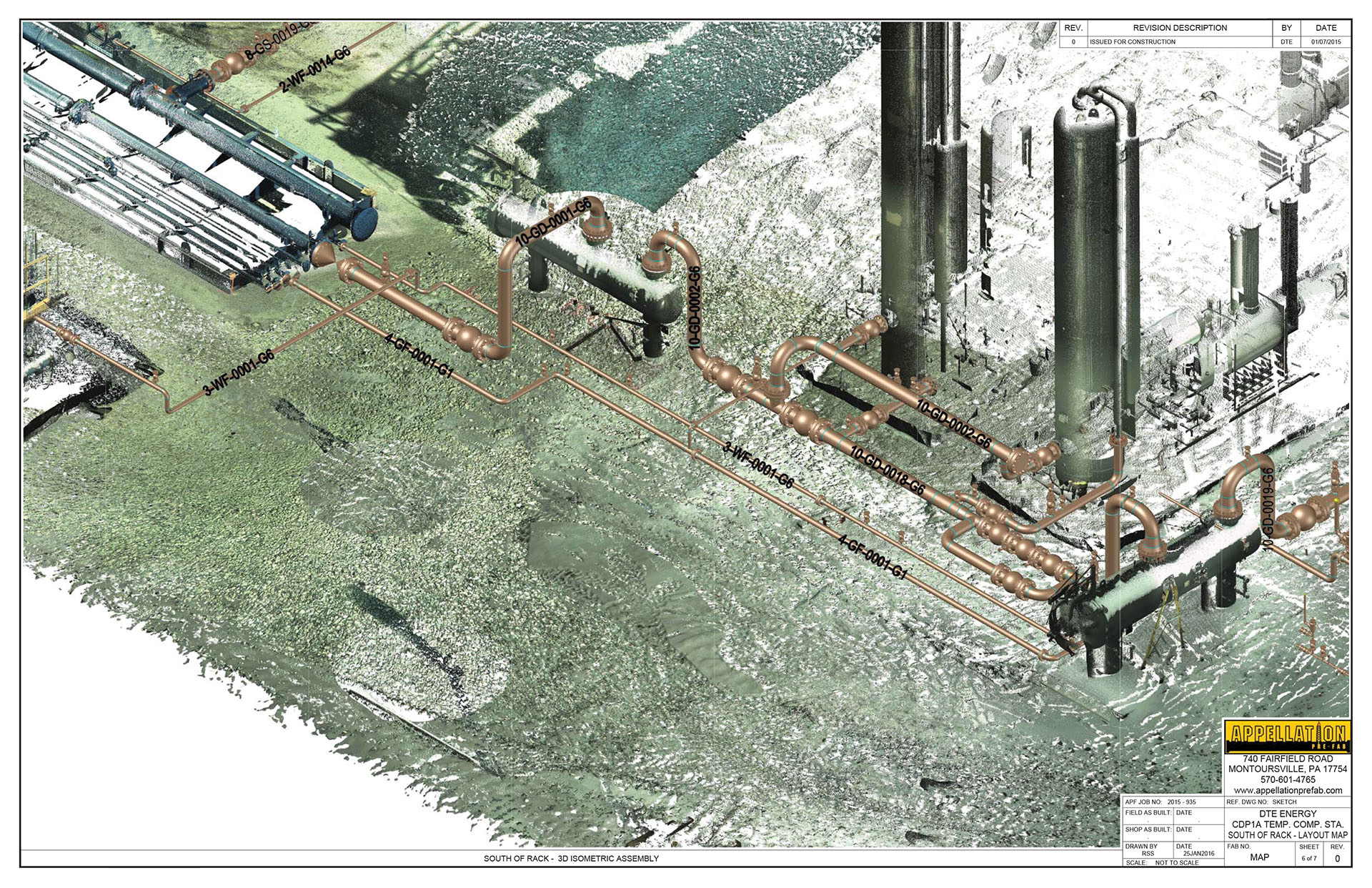

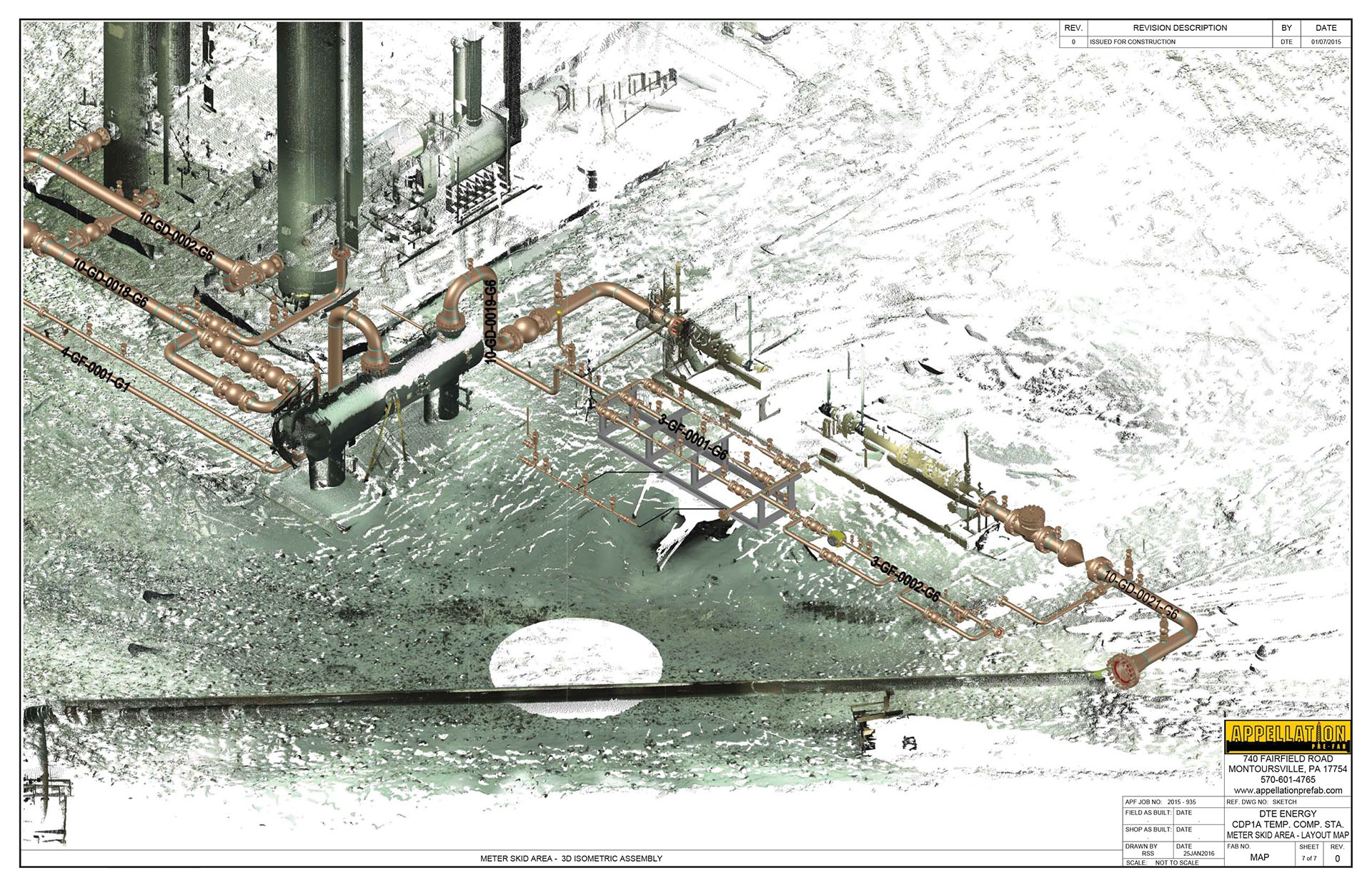

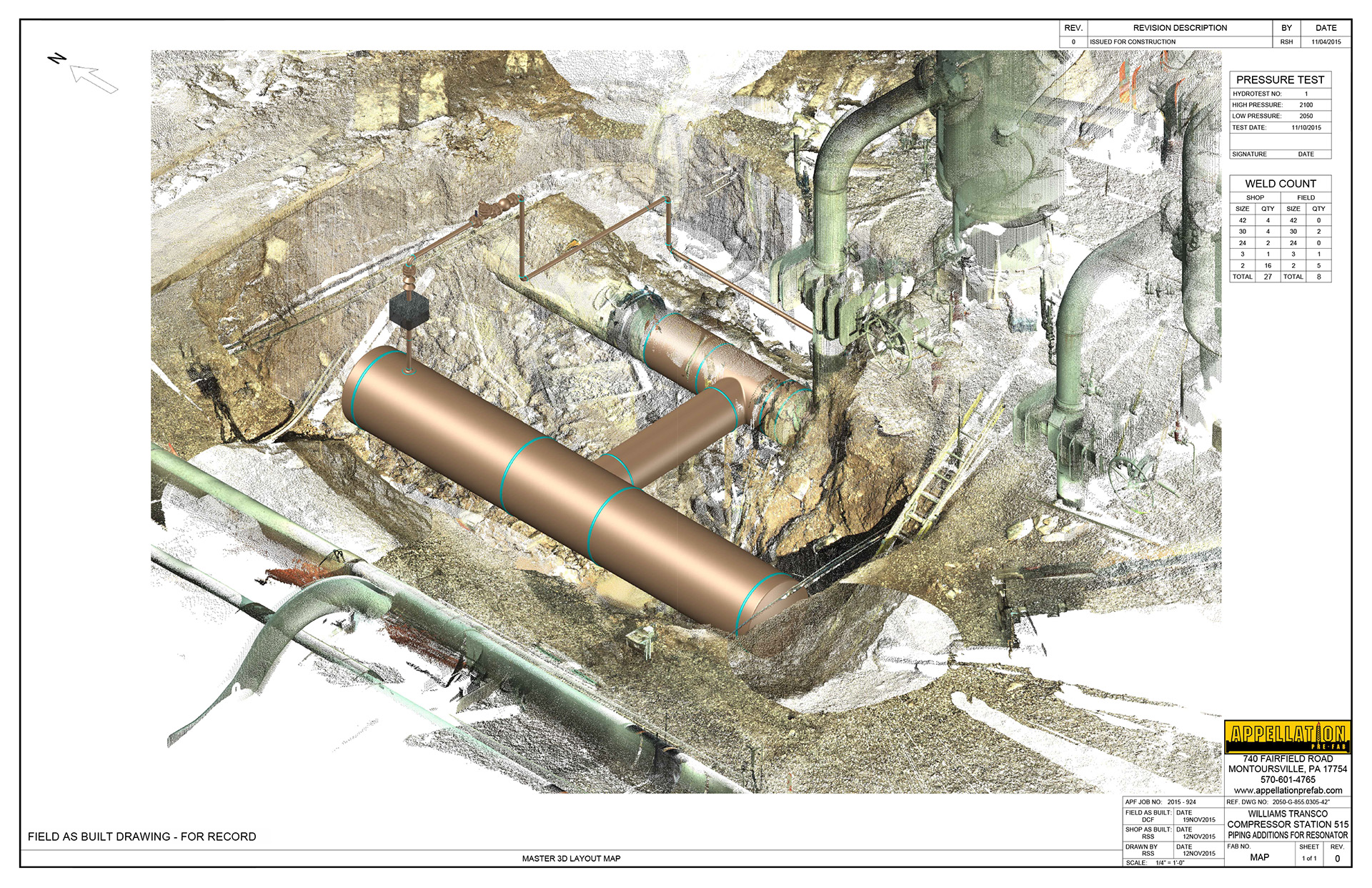

In addition to their usual fabrication drawings and turnover documentation, Appellation used Leica Cyclone software to provide the compressor station with a 3D point cloud site map with the spools highlighted in gold. “The workflows were easy, as was using Leica Cyclone,” said Schnars.

By using the Leica ScanStation C10 as well as concurrent work processes, Appellation Pre-Fab was able to deliver within the tight project timeframe. Because they were able to cut three weeks out of the typical project timing, they saved the compressor station owner time and money, leading the compressor station’s owner to say this was “an exceptionally good project.”

3D point cloud site maps facilitated compressor station installation.

How Laser Scanning Provides a Solid Return on Investment

Emick initially had some concerns about making such a large capital investment. He found the high accuracy levels that Leica Geosystems claimed the equipment would achieve to be almost unbelievable.

Appellation Pre-Fab knows firsthand the challenges of working with hand measurements. When working on a six-engine compressor station two hours away from its facility, the company had to rely on the client to provide the required dimensions. After waiting 10 days to receive the data, Schnars had drawn up designs, fabricated the piping and shipped it to the station. He was devastated when he learned that each of the pipe’s dimensions were off because of inaccuracies in the initial measurements. The piping had to be cut apart, sent back to the shop, fixed, welded, painted and shipped back to their customer.

It was a costly mishap that the company could not afford to repeat. So Bill Emick, Appellation Pre-Fab’s owner, decided to increase efficiency and cut costs by investing in technology that could avert such a situation: a Leica ScanStation 3D laser scanner. The solution promised more accurate measurements, fewer human errors transferring measurements to paper and the ability to save time and money.

Emick initially had some concerns about making such a large capital investment. He found the high accuracy levels that Leica Geosystems claimed the equipment would achieve to be almost unbelievable. Also, he was not sure how easy it would be to run the scanner and work with the data. However, after using the technology to complete well over 75 scans in the first six months, Emick was happy with his purchase decision.

To date, the Leica ScanStation has lived up to its claims of accuracy, is easy to use, and has enabled Appellation Pre-Fab to solve problems for clients and remain a leader in its industry.

HIGH-VALUE DELIVERABLES

- Fabrication drawings

- High resolution registered point clouds

- 3D point cloud site map

BENEFITS

Increased Safety

All data captured from ground level

Fast Data Collection

All data captured in two days with one scan technician vs. the 10 days with a two-person crew that would have been required with traditional methods

Accurate, Comprehensive Data Capture

Complete and accurate as-is dataset enable measurements to be accessed as needed, avoiding rework and returns to site

Better Project Visualization

3D point cloud site maps enable stakeholders to make better decisions

Reduced Downtime – perfect-fit installation means no rework