Darling was able to scan the project in one and a half days and provide a detailed, accurate 3D model of the facility the engineers could immediately use to plan their upgrades with confidence.

Over the last 15 years, digital data has become an integral part of engineering and architectural workflows. Many companies use 3D laser scan data during the design phase of facility upgrades. Darling Geomatics, based in Phoenix, Ariz., has provided 3D laser scanning services to industrial, construction, engineering, mining, energy, airport, healthcare and sports clients since 2002. CEO Mary Darling says this approach is the most effective way to safely, quickly capture comprehensive and accurate measurements.

Location

Vance, Alabama

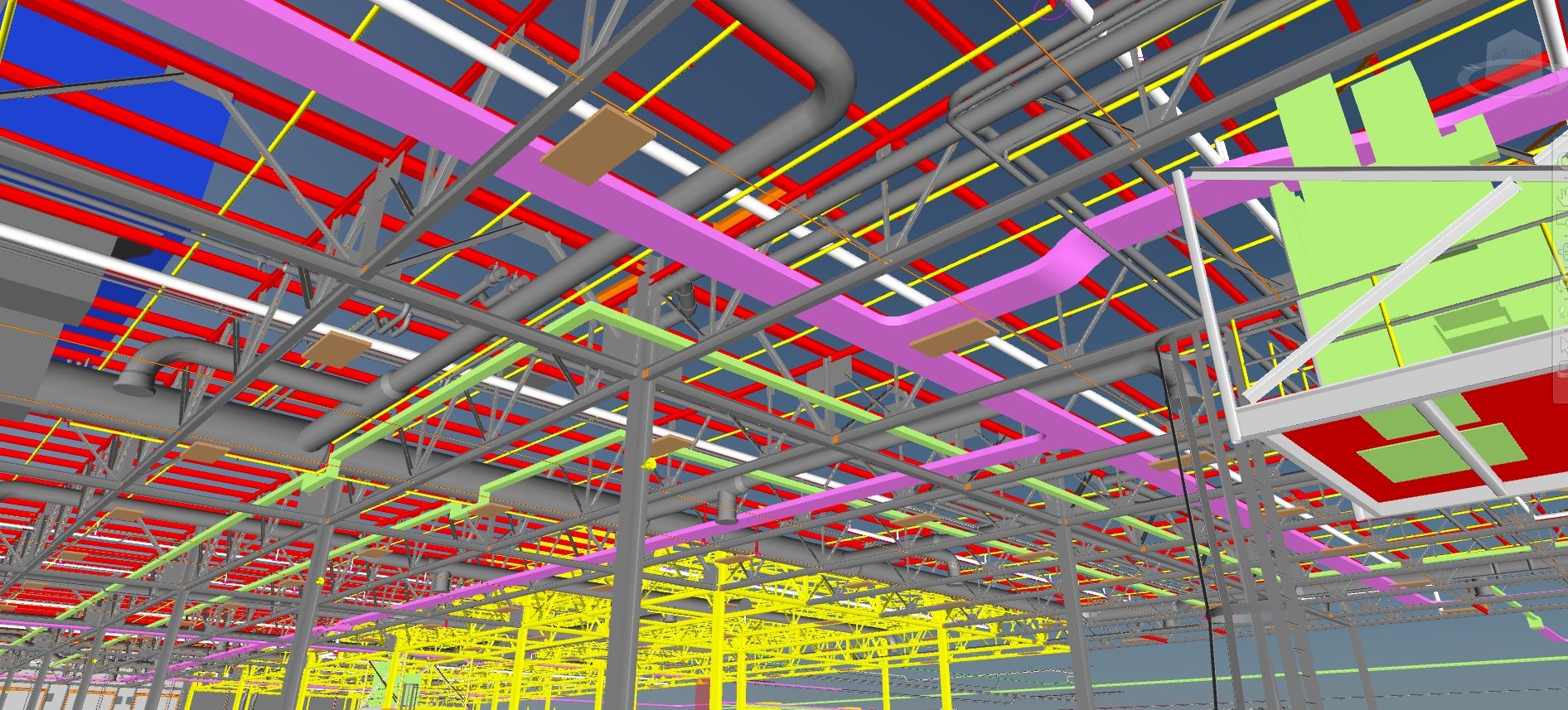

In one stunning example, the company conducted an as-built and construction verification survey on a 1.5 million square foot expansion at the Mercedes-Benz U.S. International (MBUSI) automotive plant in Vance, Alabama, with the onsite plant work completed in a matter of days. Comparing the comprehensive, accurate laser scan point clouds to the design and fabrication models proved that all major construction components were exactly in place to within a 1/2 inch, and that even less consequential elements, like lighting, were within 2 inches of design.

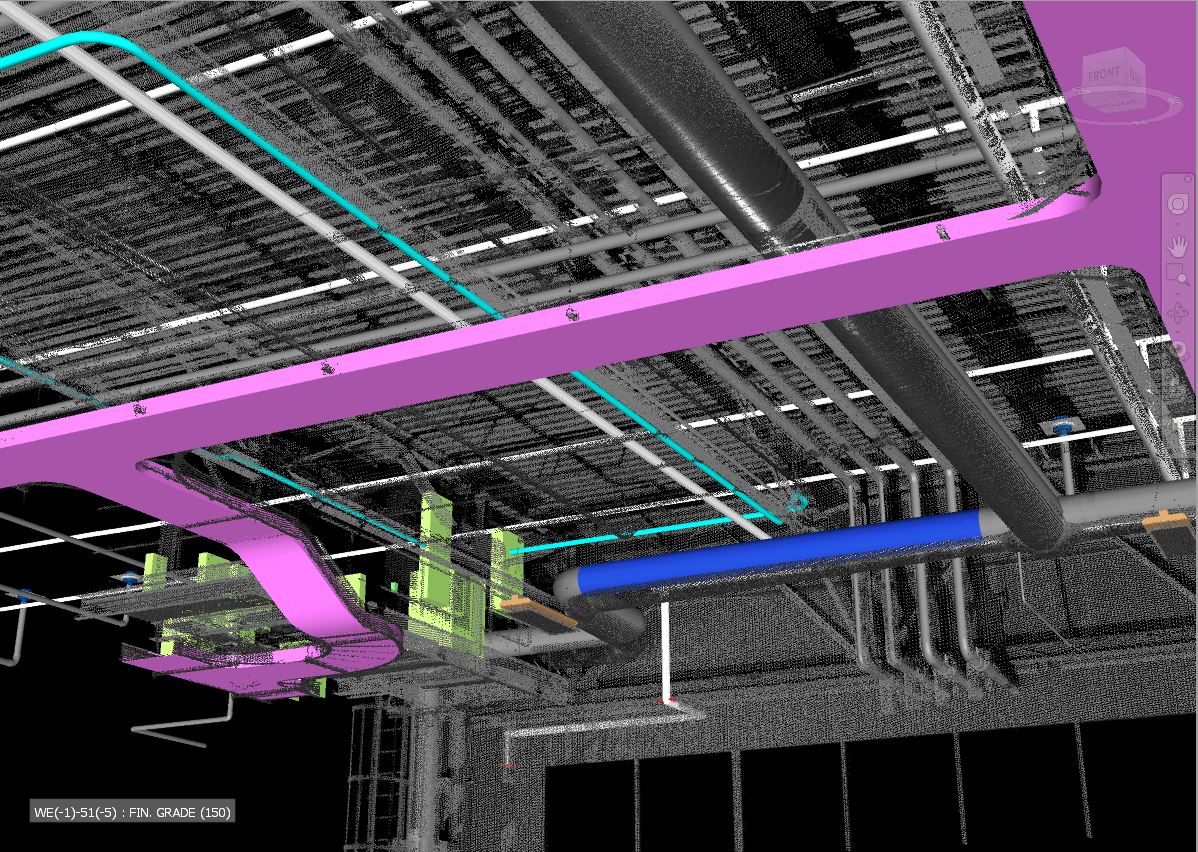

In another project, one of Darling’s clients did not have current as-built drawings when they got ready to design upgrades to their ammonia processing plant. The alternative to 3D scanning would have been for them to try to hand measure all pertinent areas of the plant. The manual process would have been dangerous as well as prohibitively time consuming and expensive. Darling was able to scan the project in one and a half days and provide a detailed, accurate 3D model of the facility the engineers could immediately use to plan their upgrades with confidence.

On average, the digital data acquired with 3D laser scanning saves four to six times the cost of the service by streamlining projects and eliminating rework and change orders. The data also enables the smart building apps, IoT processes and AI advances that are driving manufacturing plants into the future.

Over the last 15 years, digital data has become an integral part of engineering and architectural workflows. Many companies use 3D laser scan data during the design phase of facility upgrades. Darling Geomatics, based in Phoenix, Ariz., has provided 3D laser scanning services to industrial, construction, engineering, mining, energy, airport, healthcare and sports clients since 2002. CEO Mary Darling says this approach is the most effective way to safely, quickly capture comprehensive and accurate measurements.

In one stunning example, the company conducted an as-built and construction verification survey on a 1.5 million square foot expansion at the Mercedes-Benz U.S. International (MBUSI) automotive plant in Vance, Alabama, with the onsite plant work completed in a matter of days. Comparing the comprehensive, accurate laser scan point clouds to the design and fabrication models proved that all major construction components were exactly in place to within a 1/2 inch, and that even less consequential elements, like lighting, were within 2 inches of design.

In another project, one of Darling’s clients did not have current as-built drawings when they got ready to design upgrades to their ammonia processing plant. The alternative to 3D scanning would have been for them to try to hand measure all pertinent areas of the plant. The manual process would have been dangerous as well as prohibitively time consuming and expensive. Darling was able to scan the project in one and a half days and provide a detailed, accurate 3D model of the facility the engineers could immediately use to plan their upgrades with confidence.

On average, the digital data acquired with 3D laser scanning saves four to six times the cost of the service by streamlining projects and eliminating rework and change orders. The data also enables the smart building apps, IoT processes and AI advances that are driving manufacturing plants into the future.