Cloud-based solutions empower you to access your plant remotely from any location so you can keep your business moving even when you can’t be there in person.

Whether you’re seeking to avoid downtime, ramp up production to meet increasing demand, or plan ahead for the next cycle of business, the ability to quickly and easily access the data you need is more important than ever to making good decisions. You need detailed insight on every asset in your facility, from the exact location of valves and piping to the condition of conveyors and lines. Having confidence in this data and being able to access it remotely from any location empowers you to keep your business moving even when you can’t be onsite.

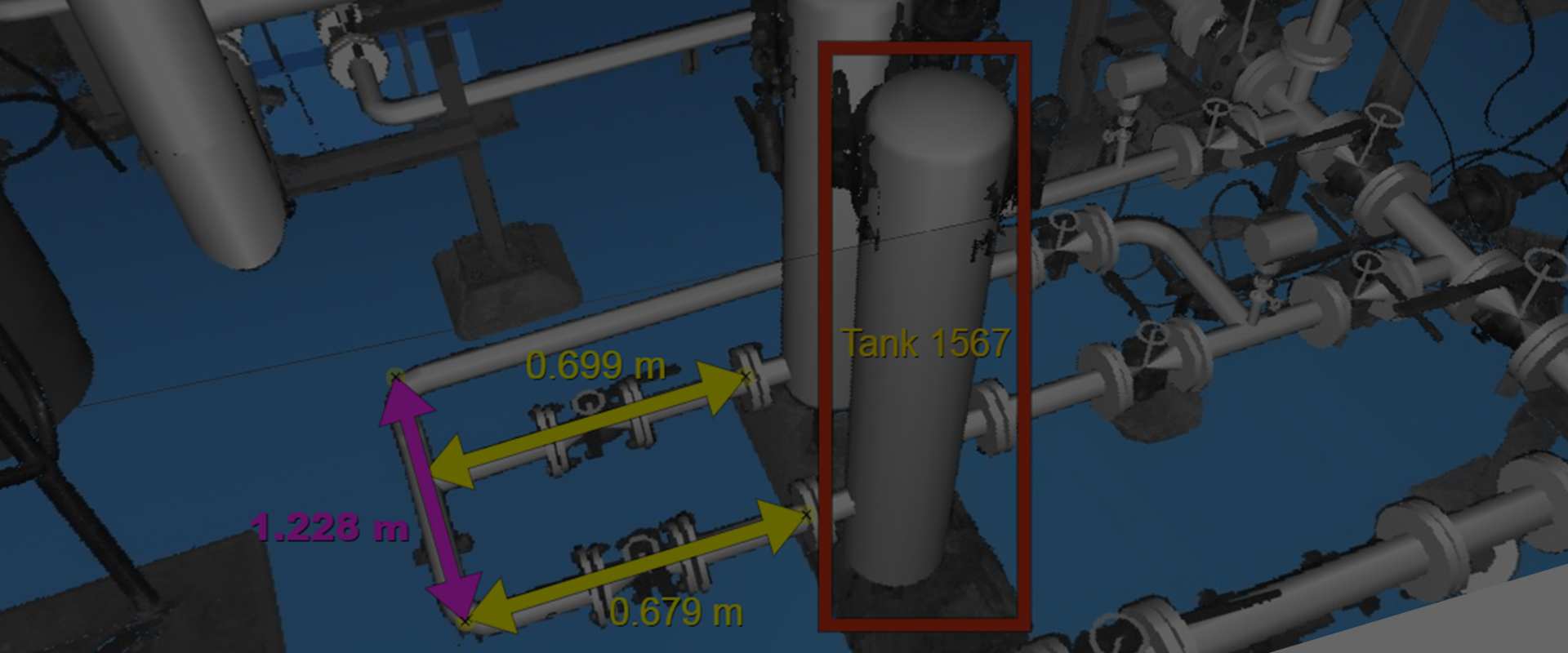

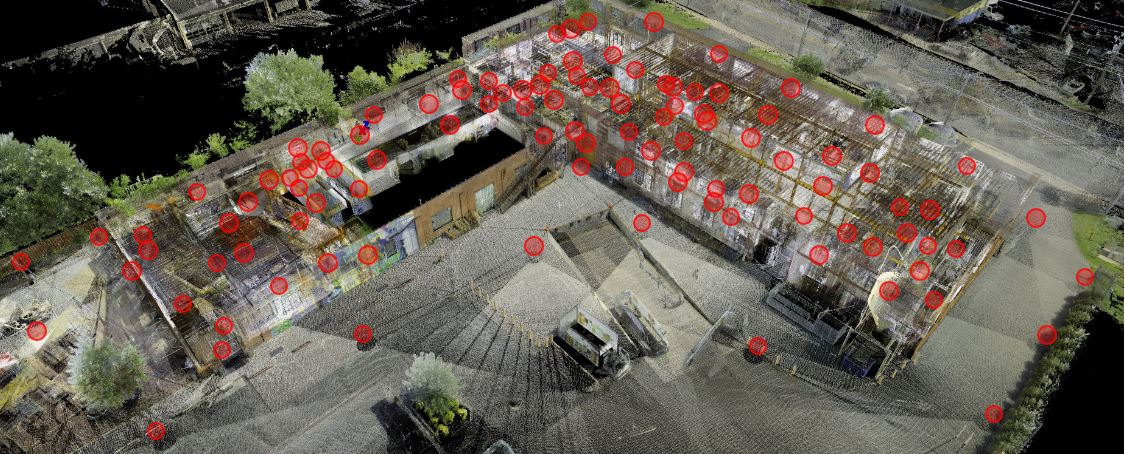

Point cloud data is remotely accessible and can give you detailed insights on your plant. Explore a sample dataset here.

Capture and Share As-Built Data Instantly

Technology advances make it possible for all project collaborators to have near-real time access to the data that matters.

3D laser scanning is crucial to meeting these objectives. A noncontact and nondestructive method of digitally capturing physical objects in 3D using a beam of light, or laser, laser scanning captures millions of measurement points on any surface. These combined points are known as a point cloud—a comprehensive, clear and precise digital record of your plant that can be used for analysis and maintenance.

Because of the speed of 3D laser scanning, the time involved in capturing complete and accurate as-built data drops from weeks to hours—or even minutes. The fastest laser scanner available completes a full scan in as little as 26 seconds. This means you can capture comprehensive data in a fraction of the time compared to other measurement methods. All of this data can be collected safely with a single operator working alone.

Once the data is captured, cloud-based software enables you to quickly and easily access the data from anywhere on any device, even if you aren’t familiar with CAD or 3D datasets. You can virtually visit the site without any safety concerns or delays, take snapshots, make measurements, and create markups with notes and links. Recent software advances have made it possible for collaborators around the world to have near real-time access to the rich project data, including measurable images, layers of rich visualization and tags that contain useful notes and project context. While offsite, you and other collaborators can access, view and analyze the work as it progresses and provide feedback to ensure that all areas of interest have been captured to project specifications. Point cloud data including tags can be shared directly from the field to provide a dimensionally correct and photorealistic view of the plant. You maintain full control over who sees what data and who can make changes.

RELATED: See how to get instant access to every detail of your plant with digital remote management.

Measure from images and access tags that contain useful notes and project context. Try it for yourself here.

Find New Ways to Succeed and Thrive

By making your plant lean, agile and easily accessible in a virtual environment, you can adapt to an ever-evolving landscape.

If it all sounds too easy, that’s because it is. We live in a world where innovation and technology enable us to overcome hurdles and create new solutions. Our imagination in how we apply these solutions remains our most powerful resource. We have at our fingertips the ability to make our industrial plants lean, agile and easily accessible in a virtual environment so we can make the decisions that allow us to adapt to an ever-evolving landscape. Our biggest challenges also present our greatest opportunities.

The need for automation and accurate 3D data will only continue to increase in the future. Now is the ideal time to learn about technology and develop a strategy for how to implement new ways of operating that will position your plant not only to survive, but to thrive.

To talk through ideas or gain more insight on how to leverage 3D data to maximize your plant operations, connect with me or my team.