Adapting to change can’t begin until you have a starting point. Having complete, accurate point cloud data from laser scanning allows you to make decisions faster so you can design, plan and implement the changes that will help you modify your operations, increase your efficiencies and generate more revenue.

How are you feeling about your manufacturing operations? If our current situation has taught us anything, it’s that we have some fragile components in our economy. Supply chains in some sectors have been crushed, while others are struggling. Companies that were unable to quickly shift gears and create demand on their own have had to close their doors. Even as states have begun reopening their economies, some of the manufacturers I’ve been talking to are feeling stuck because they can’t afford to make a change right now.

Company

Any

Location

Any

Others have an ace up their sleeve: A digital remote manufacturing strategy.

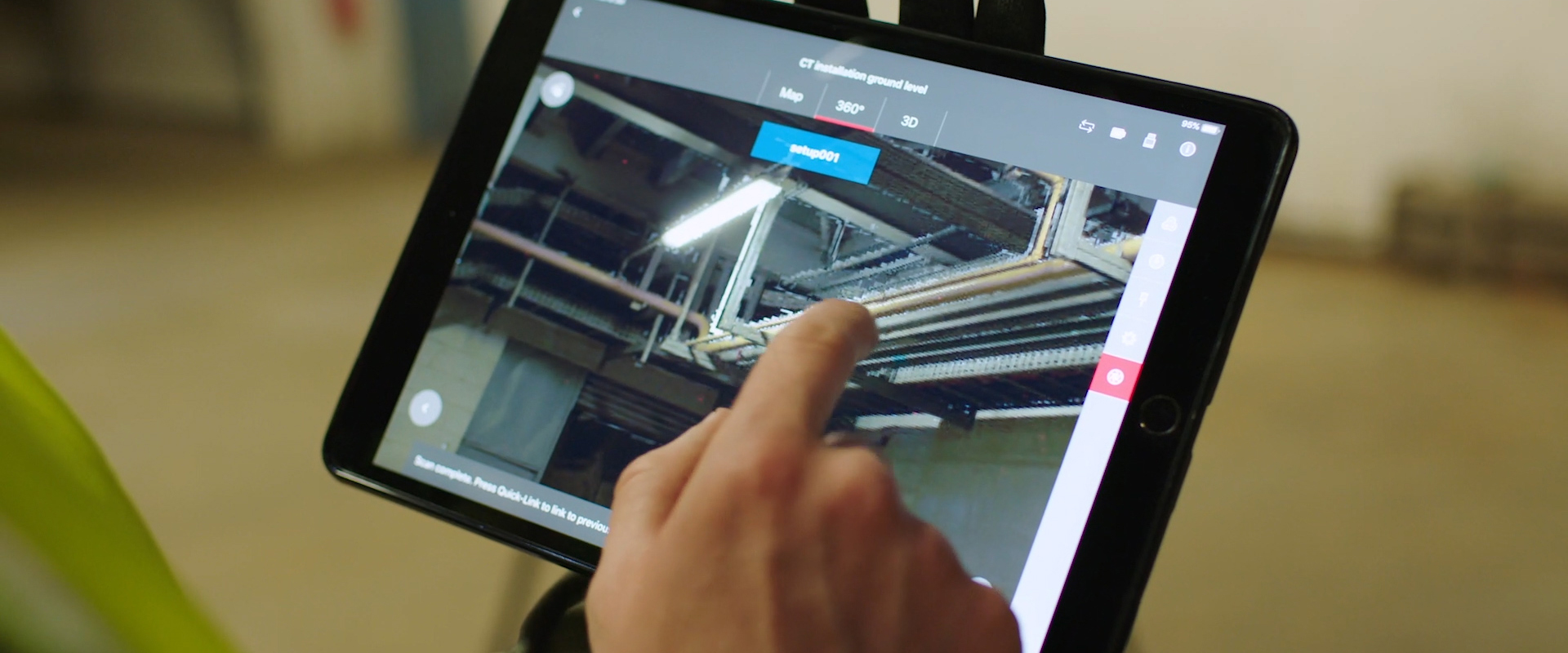

Over the last decade, the idea of digital as-built data has become increasingly popular as the technology to capture that data has become accessible and easy to use. Forward-thinking manufacturers have carefully constructed a digital twin of their facilities and production lines as they planned ahead. While they undoubtedly didn’t account for a global pandemic, the need for agility and efficiency that drove them to invest in laser scanning now positions them at the forefront of a rebound.

Related: Explore the benefits of a digital twin

Laser Scanning Makes It Possible

If you’re not there yet, now’s the perfect time to take the first step. In fact, many believe that manufacturing is about to take a giant leap forward. But adapting to change can’t begin until you have a starting point. Having complete, accurate point cloud data from laser scanning allows you to make decisions faster so you can design, plan and implement the changes that will help you modify your operations, increase your efficiencies and generate more revenue. Product flexibility and the ability to adapt to new opportunities will allow your business to remain resilient regardless of outside influences.

Creating a digital replica of your facilities also enables you to share that information remotely with other stakeholders throughout your organization. As social distancing remains a way of life for the foreseeable future, enabling remote digital access across your entire operation is one way to maximize safety while ensuring effective training and preventive maintenance.

And when you are ready to move forward on a capital improvement project, laser scan data will help you get it right the first time without impacting your production. Laser scanning only needs one person to run the equipment, and that person can get in and out quickly while capturing all the necessary data. Processing time in the office is also handled quickly since most of the registration can be done in the field. (Related: See how a true digital twin puts your plant at your fingertips.)

“Failing to prepare means preparing to fail” – this well-worn adage, has, unfortunately, proven true. If you haven’t yet been able to make the changes in your industrial plant that you know are needed, try starting with the data. Tools already exist to capture reality and provide the information you need to build a well-informed strategy. Harnessing the data can help you realize a new future that is agile, resilient and unassailable.

Now’s the time to ride the digital transformation wave and don’t look back.