"Among the engineers, project managers, and operations personnel at my local facility there is never any question that every project begins with scanning; the value that it adds to projects is evident."

In the transportation and processing of oil, natural gas, liquefied natural gas, chemicals/petrochemicals and other materials, changes to pipes, pumps, tanks and other equipment are needed frequently. Asset management is understandably a challenge — yet maintaining accurate, accessible documentation of assets is the only way to fully optimize plant performance.

Through advances in reality capture technology, capturing and managing every detail of a facility has become fast and easy, laying the foundation for a comprehensive digital twin that delivers substantial ROI in project planning and implementation, operations and maintenance, training, and every other aspect of plant management.

“Among the engineers, project managers, and operations personnel at my local facility there is never any question that every project begins with scanning; the value that it adds to projects is evident,” explains one senior engineering technologist.

The Why and How of Laser Scanning

Laser scanning is a noncontact and nondestructive method of digitally capturing physical objects in 3D using a beam of light, or laser. The laser scanner captures millions of measurement points on any surface. These combined points are known as a point cloud—a comprehensive, clear and precise digital record of the real-world environment that can be used for design and engineering, analysis, and even maintenance.

These point clouds close the gap that exists between the CAD model of a system, where everything is drawn level, square and plumb, and the actual working system in the plant, which is fraught with irregularities. By matching new designs to the accurately captured point cloud instead of a CAD model, designers and engineers increase the accuracy of their work, avoid rework, and save time and money.

Incorporating laser scanning into a process requires addressing several key issues. First, the business case for laser scanning must be clear—the technology should provide a fast return on investment. Additionally, the hardware and software should be easy enough to use right away without requiring a long learning process. And experiencing the full value of digitization requires a plan for suffusing the technology into the organization and achieving buy-in from all stakeholders.

The extensive—and growing—track record of laser scanning with Leica Geosystems scanning solutions in oil and gas and other plant environments makes it easy to build a compelling business case up front for the use of the technology.

Business Case

Before asking management to make the investment, you need to lay out a strong argument that the laser scanning technology will give a good ROI. The extensive—and growing—track record of laser scanning with Leica Geosystems scanning solutions in oil and gas and other plant environments makes it easy to build a compelling business case up front for the use of the technology. In fact, actual results often outperform estimates. “We had a full ROI in a matter of three or four months,” says one engineer after investing in the Leica RTC360, the latest state-of-the-art from the industry standard name in laser scanning, along with Cyclone REGISTER 360 point cloud processing software and CloudWorx CAD plugins. Such results are not uncommon, even among new users of the technology.

Ease of Use

Even if you will be the primary engineer using the laser scanner, you should be able to hand off scanning projects to others on your team. Ease of use of both the hardware and software is crucial in technology selection. Many engineers prefer the RTC360 for this reason—it is small enough and intuitive enough that you can begin using it on projects immediately. Anyone who has had some CAD 3D modeling experience can pick it up and run with it and have confidence in the accuracy of the data. And the CloudWorx software makes it easy to fit designs to the point cloud.

Universal Adoption

Success in one instance does not mean the rest of the organization will embrace a new approach. Any technology, however valuable, will languish unless a large fraction of the organization embraces it as standard procedure. Exemplary ROI, careful record keeping, and a transparent approach to projects are essential in securing the buy-in from other designers and engineers that will maximize results.

The Impressive Savings of Digital Transformation

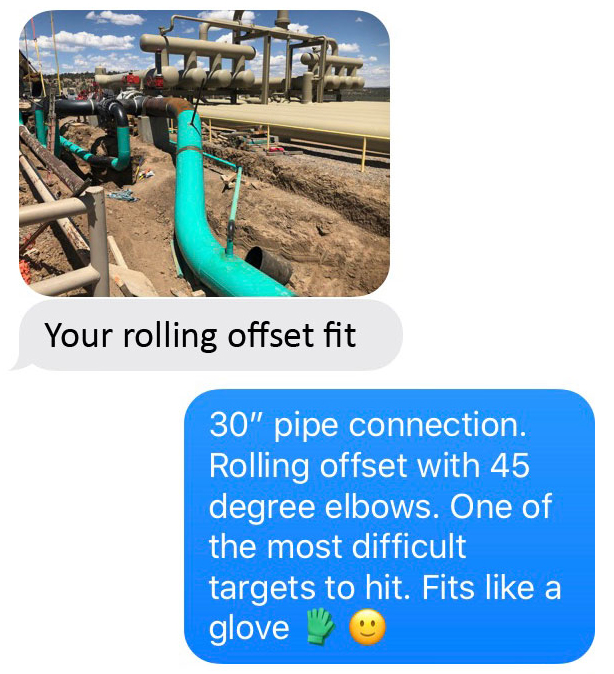

What kind of results can you expect to achieve with laser scanning? Many projects document the benefits. One example is in the installation of a line cross-over and pig launcher to increase flow options and efficiencies in the piping junction at an oil and gas facility. Achieving the cross-over required creating a common connection between three pipelines, all converging at different elevations and at compound angles to each other—a feat that would have been extremely difficult using traditional measurement and documentation methods.

“Using the point cloud captured by the RTC360, LGS file exported by Register360, and CloudWorx for BricsCAD, we were able to design and prefabricate the new piping,” explained one engineer. “The fit-up of the resulting piping spool was perfect.”

According to the project manager and gathering system engineer, the scanning process saved the company two full days in the field compared to traditional (stovepipe) methods—equivalent to $15,000 per day for a full crew of laborers, a welder, and an excavator. That’s on top of savings from reducing shutdown time and lost production, which engineers estimated to be around $24,000 for two days. “That equates to a staggering $54,000 the RTC360 saved us on its first project,” said the engineer.

Another noteworthy project was the replacement of a corroded 90-foot-tall tower on an amine stripper. Measuring the tower through traditional means would have required the hazards of climbing ladders and scaffolding along with days of work to document the measurements and create the models. Using the RTC360 laser scanner, engineers scanned the piping from the ground in a matter of hours and used the point cloud to quickly model the tower and piping to ensure a new tower could be fabricated offsite without visits from the manufacturer. “It was a shining success,” said the project lead. “The new tower fit perfectly, and no modifications were necessary. Having that peace of mind of knowing that when you get this piece of equipment it’s going to fit—that’s very valuable.”

More recently, laser scanning was used on an area of fuel gas piping at a gas processing plant. The resulting piping spools were fabricated off-site, put through nondestructive testing, and painted. On shutdown day, a small crew of laborers bolted up the new piping spools. They fit perfectly. Using laser scanning in this case eliminated the need for hot work inside of the plant, providing enhanced safety by reducing risk, and saving costs and shutdown time.

When everyone knows exactly where to find the information they need and has confidence in the data, all operations see continuous improvement.

The Undeniable Benefits of Clean, Accurate Point Clouds

Transitioning to a digital plant documentation process with laser scanning provides a host of documented benefits.

- The 3D visualization provided by point clouds and improved CAD models makes communications with construction contractors much easier and quicker. This leads to more accurate and competitive bids.

- The accuracy of the drawings based on real-world conditions captured with laser scanning removes ambiguities and redundancies. New designs of piping and other structures, when matched to the point cloud of the existing structure, are guaranteed to fit correctly when installed.

- Because the point cloud data is easy to access and view, everyone has a better understanding of the as-is structure, which leads to fewer clashes and fewer re-workings of designs.

- Having an accurate digital duplicate of the plant available instantly on their desktops means the engineers make fewer trips to the field. This reduces the costs and helps to keep the project schedules tight. The combined benefits of scanning – fewer trips, fewer requests for clarification, more shop fabrications instead of field fabrications, etc. – contribute to shortened project schedules. Tight project schedules provide significant savings.

- The ability to access the plant virtually through online web viewers – a concept known as digital remote management – enables operations to train staff offsite.

- Making the virtual, accurate point cloud measurements part of the project documentation ensures that regulatory, legal, and other requirements are more easily satisfied.

- Safety is always a vital consideration. No longer do employees or contractors need to erect scaffolding and climb about the piping, pumps and other equipment to take a few measurements of an area destined for change. The laser scanner takes millions of measurements, far more accurately, from the floor and walkways. It also eliminates downtime from shutdowns that would otherwise be required to capture measurements on equipment in operation.

The ability to fit up 100% of prefabricated piping perfectly the first time has a significant impact on a plant’s bottom line. More importantly, having comprehensive 3D digital data also changes how everyone thinks about the facility. When everyone knows exactly where to find the information they need and has confidence in the data, all operations see continuous improvement.

This thoughtful, clever approach to digital transformation can save hundreds of thousands of dollars over the cost of adopting laser scanning technology and create a new standard for plant engineering.