Global information Systems’ innovative approach to 3D asset management empowers companies to maximize operational efficiency, environmental sustainability and regulatory compliance.

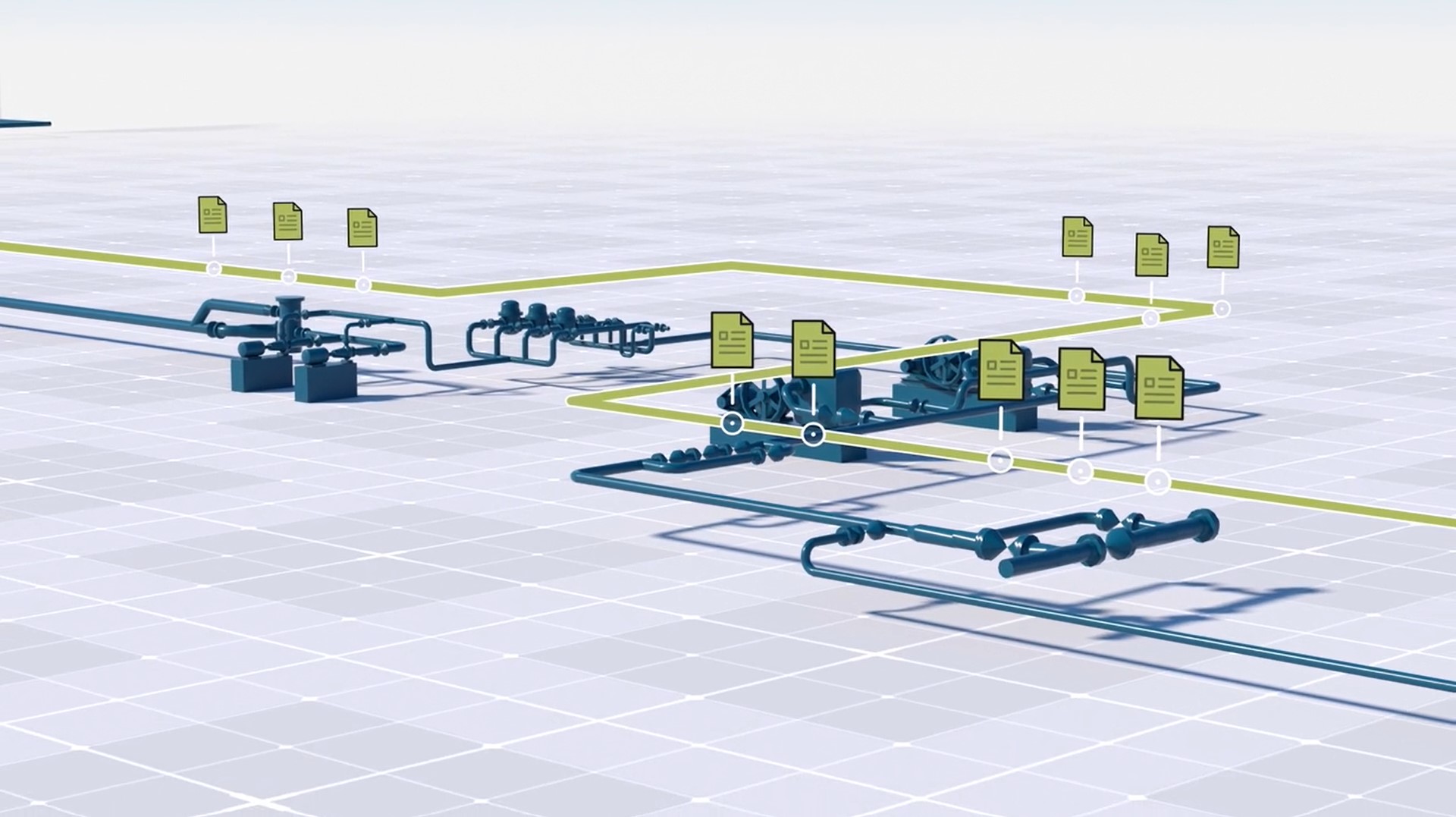

Thousands of miles of pipelines. Hundreds of terminals. Dozens of fabricated compressor and metering stations, flare stacks, and other structures. All precisely located and managed through one accurate digital model that shows every piece of pipe, valve, fitting and weld complete with the diameter, grade, ANSI Class, wall thickness, coating, and inspection circuit or pressure zone.

Once considered a futuristic ideal, this level of intelligence is rapidly becoming standard for the oil and gas industry as companies seek to maximize efficiency, sustainability and regulatory compliance.

Location

Headquartered in Lexington, KY, with offices in Texas, Georgia, Missouri and Maine

“Operators need to know what they have, where it’s at and what condition it’s in—not just for their pipelines, but also for all their fabrications and facilities,” says Eric Klein, vice president of Global Information Systems. “Technology advances over the last several years make it possible to achieve sophisticated 3D asset management quickly and easily.”

With 3D laser scanning, we’re capturing every detail accurately in minutes. The continued innovation in the technology is transforming our ability to build incredibly accurate digital models that can be used to efficiently operate and manage assets and keep them in compliance.

- Eric Klein

Laser Scanning Captures Reality

Global, which is based in Kentucky with offices in Texas, Georgia, Missouri and Maine, provides pipeline and facility integrity services and construction performance management for clients in the oil and gas industry. The company provides expertise in data analysis, modeling, mapping, integration and reporting. Offering an array of solutions to modernize and optimize operations to ensure efficiency, safety and regulatory compliance, Global has been at the forefront of digital asset management technologies utilizing 3D laser scanning capabilities. However, as technologies advance and customers realize the potential of data visualization, Global has made strides to diversify its data capture abilities to meet its clients’ specific needs using Leica Geosystems’ latest imaging laser scanners.

“We’ve always provided an asset management service, but the traditional approach of working from 2D drawings and hand measurements was time-consuming, onerous, and, frankly, prone to error,” explains Klein. “With 3D laser scanning, we’re capturing every detail accurately in minutes. The continued innovation in the technology is transforming our ability to build incredibly accurate digital models that can be used to efficiently operate and manage assets and keep them in compliance.”

3D asset management based on comprehensive and accurate laser scan data addresses regulatory requirements and also answers any other questions that might arise about as-is conditions in the facility.

The company’s journey into reality capture began several years ago when Klein discovered they could lease a professional survey-grade ScanStation P-Series laser scanner from Leica Geosystems. After testing and training, they put the laser scanner to work scanning projects with large facilities and almost immediately saw a threefold increase in productivity compared to plant documentation with manual processes.

“We already had a team dedicated to 3D modeling, so we formed another team dedicated to learning and using the laser scanning hardware and software that integrated with the 3D modeling team,” explains Klein. “We were up and running pretty quickly.”

Laser scanning is a noncontact and nondestructive method of digitally capturing physical objects in 3D — “reality capture” — using a beam of light, or laser. The laser scanner captures millions of measurement points on any surface. These combined points are known as a point cloud — a comprehensive, clear and precise digital record of the real-world environment that can be used for design and engineering, analysis, and even maintenance. Unlike CAD models, in which everything is shown level, square and plumb, point clouds capture the actual working system of pipelines and facilities the way they exist in the real world, with all of their irregularities.

Although Global’s clients didn’t initially interact directly with the point clouds, they did notice the rich detail of the 3D models developed from laser scanning, and they appreciated the rapid turnaround on deliverables. The more clients learned about the technology Global was using to capture the data, the more they wanted to expand digital asset management across their entire operations. There was just one challenge.

“We had a client that needed us to digitally document thousands of small facilities and fabrications to meet regulatory requirements,” says Klein. “The amount of time required to set up and break down the P-Series laser scanner was prohibitive in this application, but the value of laser scanning was evident. We had to find another solution.”

Technology Innovation Maximizes Efficiency and Value

Global had already been exploring other laser scanners. In early 2020, Klein launched an R&D program to focus on 3D laser scanning and downstream capabilities. With each new technology release from different manufacturers, the company researched and experimented. Their standards were uncompromising. “What Leica makes are professional grade industrial grade tools and software that we know will deliver,” Klein says. “Nothing else came close.”

Then, in early 2021, a Leica Geosystems technical representative suggested they field test the Leica BLK2GO, a handheld imaging laser scanner that creates a 3D digital twin while the user moves through a space. “We got a demo unit, tested it out, and bought it right away,” Klein says.

After a weekend of testing, Global’s laser scanning team was confident enough in the quality of the data that they mobilized it for their project documenting the small facilities. “Our productivity went through the roof with the BLK2GO,” says Klein.

The Leica BLK2GO handheld imaging laser scanner captures points clouds as you move through a space, making it ideal for as-built data capture in small or complex industrial plant environments.

The team was capturing entire facilities in 30 minutes or less, making quick progress in the capture of thousands of facilities over hundreds of miles. The data capture was done with a single scanner operator onsite with no impact to the facilities’ operations.

The Global team quickly built a model of the assets from the laser scan data and added layers of intelligence that could be used to maintain, analyze and report on asset type, location, status and condition.

When the client saw the deliverables, they were stunned. “They were expecting a 2D deliverable,” says Klein. “Once we showed them the much better 3D product and how quickly we could get it, they loved it. Now they’re showing it to other departments that are saying, ‘We want that.’ And it’s only possible because we’re able to get quality laser scan data captured in a timely manner.”

The client’s project manager was so intrigued by the technology that he decided to follow Global’s team around for the second week of data capture — and he brought the regulator with him. Within a few days, the auditor said he was satisfied with the process and had seen enough.

“Using the 3D laser scan data, we were able to build an intelligent model that not only addressed the regulatory requirements but also answered other questions the company might have about their assets, even questions they hadn’t thought of yet,” Klein says. “They’re still finding new ways to apply the information.”

There’s no better way to achieve regulatory compliance and operational value than with digital asset management based on reality capture.

- Eric Klein

Increasingly, clients are also beginning to see the value in the underlying point cloud data. Klein says one client uses the point cloud to create virtual facility walkthroughs for training and virtual field visits. Another client is allowing Global to push the envelope of what 3D asset management could be — capturing multiple large facilities with full-size tank farms, pump stations, terminals and piping; linking P&IDs to intelligent models; integrating the data into a geographic information system (GIS) and other systems; and continuously updating the digital twin with more field data collection. The insight gained through this approach enables the owner to easily manage multiple facilities remotely.

While Global now primarily uses its BLK2GO for laser scan data capture due to its tremendous speed and flexible form factor, Klein appreciates that he still has the option to lease the P-Series and other laser scanners from Leica Geosystems. The ability to use a fit-for-purpose solution for every project gives the company confidence as it continues to grow its high-value 3D asset management service.

“The digital twin isn’t new, but historically the data has been siloed,” says Klein. “We’re liberating that data by capturing reality in the best possible way with 3D laser scanning then making the data shareable so you can integrate with it, update it, manage and analyze it.

“There’s no better way to achieve regulatory compliance and operational value than with digital asset management based on reality capture.”

Digital Remote Management