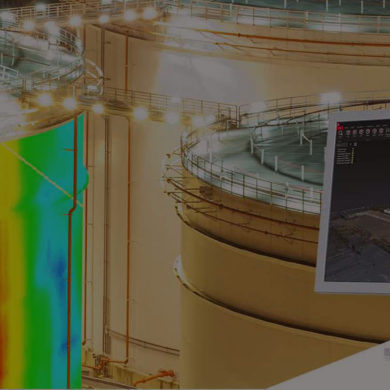

Explore how 3D laser scanning is taking tank gauging high-tech and enabling a giant leap forward in safety, speed and accuracy.

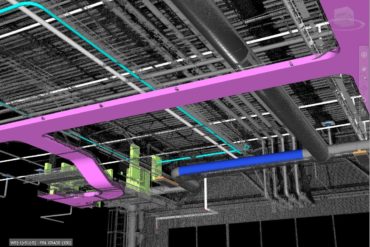

Learn new and existing workflows with Cloudworx, and see how these updates can benefit your business.

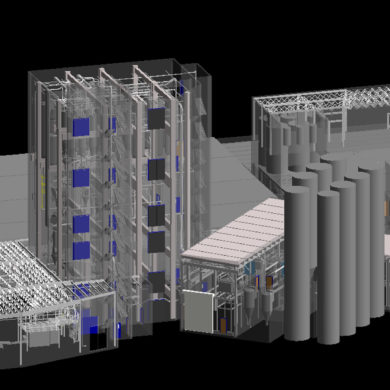

When new food storage silos need to be installed in a confined space, laser scanning offers a way to maximize safety, efficiency and mobility.

Now more than ever, having a digital twin built on accurate as-built data makes all the difference in your ability to respond and rise to the challenges.

The digitalization of tank maintenance and analysis through reality capture is a proven way to increase safety and reduce risk.

3D laser scanning is the most effective way to safely, quickly capture comprehensive and accurate measurements.

The ability to adapt and innovate its manufacturing approach positions a food processing company for continued success well into the future.

If you’re still using traditional tank gauging, you may be putting your organization at risk. Read why 3D digital tank analysis is the best approach.

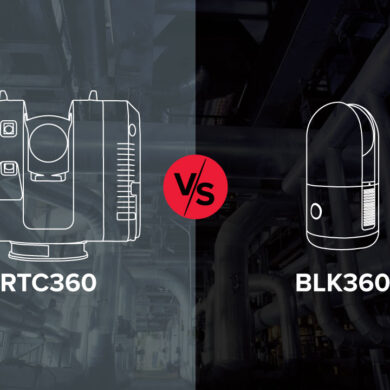

Which laser scanner is better? The answer might surprise you.

Starting with accurate, comprehensive digital as-built documentation on your existing facility can give you the solid foundation you need to build a successful future.