"We get every project right the first time. That’s what differentiates us from other laser scanning service providers." —Ricarcdo Artiga, Principal at RZA Technologies

- RZA Technologies specializes in high-precision laser scanning and CAD modeling for industrial plants.

- The company adheres to a well-established process and is known for the consistency and quality of its deliverables.

- Using laser scanning and surveying technology from Leica Geosystems provides confidence in the data quality and outcome. LEARN MORE >

- RZA Technologies’ approach includes guidance on using the resulting 3D as-built database to develop engineering solutions, plan for maintenance, and assist in future projects, helping clients realize value beyond the initial project.

- The combination of the best technology with a proven, consistent process recently enabled RZA Technologies to complete a large-scale paper machine as-built data capture—including more than 5,100 high-res, full color scans—in just 72 hours for Sappi North America. Thanks to the high quality of the deliverables, the paper machine rebuild project was completed quickly and seamlessly with no rework required.

Laser scanning is widely recognized as the fastest, safest way to capture comprehensive as-built data in an industrial facility. But there are ways to make it even faster.

RZA Technologies, a laser scanning and CAD modeling service provider based in Greensboro, NC, has developed an approach that consistently provides fast-turnaround, high-quality results, even on complex projects.

RZA Principal Ricardo (Rick) Artiga has more than a decade of laser scanning experience across a wide range of industrial plant environments. According to Rick, there are three keys to successful industrial plant scanning: using the right technology, adhering to a well-established process, and providing consistent, high-quality deliverables.

“We have a well-established process that we don’t sway from regardless of the project or site, and our product is consistent,” he says. “We get every project right the first time; that’s what differentiates us from other laser scanning service providers.”

For technology, RZA relies on Leica Geosystems laser scanners and total stations, specifically the RTC360 and TS16, respectively. “The RTC360 has proven to be a great scanner,” he says.” And we get great support from Leica—that’s one of the reasons we rely on Leica products.”

—————-

RELATED: 4 Ways the Leica RTC360 Delivers on Complex Plant Documentation Projects >

—————-

While Rick and his team of engineers, architects, and designers are known for handling complex projects efficiently, there have been a few projects that tested their capabilities. One recent assignment for Sappi North America proved why RZA Technologies’ laser scanning services are in such high demand.

More Than 5,100 Scans in 72 Hours

Sappi is a leading global provider of everyday materials made from wood fiber-based renewable resources. The company produces both raw materials and end-use products such as packaging and specialty papers.

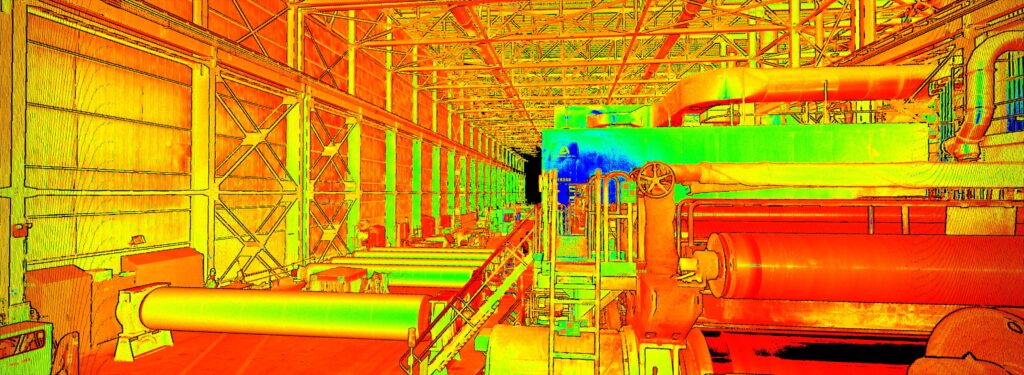

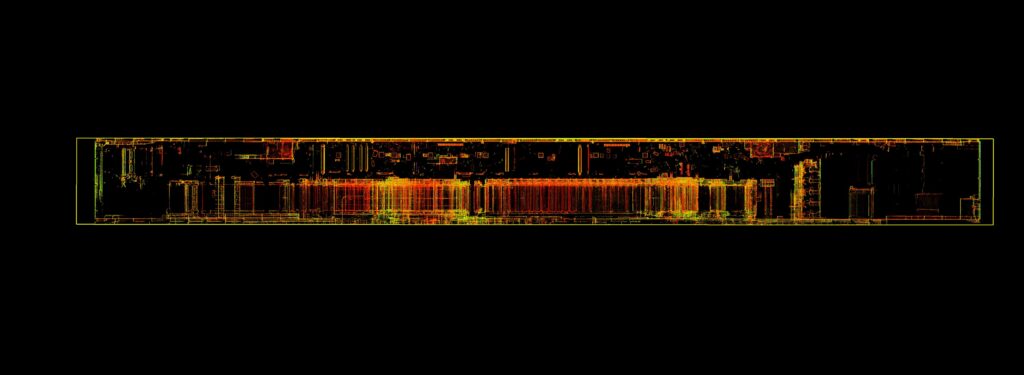

Sappi North America operates a paper mill that stretches over 1/4 mile with a basement, operating level, and mezzanine, and houses three paper machines. Each paper machine is housed on the operating level and also comprises multiple levels.

When Sappi made the decision to rebuild paper machine number 2 (PM2) to produce paperboard, they knew they would need laser scanning to capture as-built documentation on the existing machine. Components for the rebuild would be engineered and prefabricated globally. To meet demand, the paper mill operates continuously; however, Sappi had scheduled a 72-hour shutdown of PM2 for maintenance. As-built documentation on PM2 would need to be collected during this timeframe and made available remotely in a digital format to ensure that all prefabricated machine components would fit precisely with no rework. Laser scanning was the only way to achieve these goals—but the timing was extraordinarily tight.

“After receiving the news that we would have an upcoming opportunity for downtime, I called Rick to see if RZA would be available to scan our machine, on only three weeks’ notice, for our project to rebuild paper machine number 2,” says Zachary Nash, Sappi Project Elevate Engineering Manager. “Our major vendors and partners on the project would need these scans to develop the point cloud and build the 3D model of our new machine.”

The other catch? The downtime was scheduled for the week after Christmas in 2022.

RZA Technologies takes project complexity in stride

To meet the project’s precision and accuracy requirements, Rick went to the site ahead of time and laid out all the scan positions and targets and fully prepped the site. Once the shutdown started, the race was on to complete the as-built data capture.

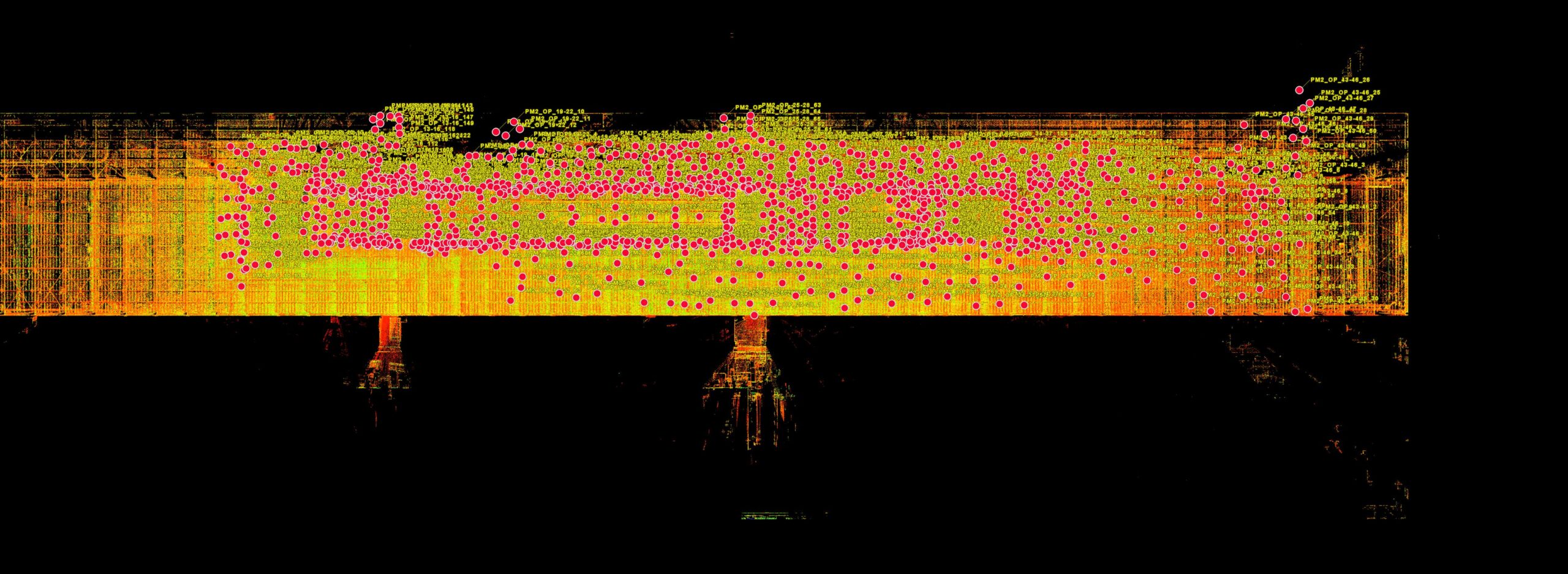

RZA employed a 10-person team working in shifts with five Leica RTC360 3D laser scanners operating continuously over the 72-hour shutdown. The team captured 5,100 scans of PM2, seamlessly surveying, scanning, importing/pre-registering the data, and finalizing the registrations. They also captured an additional 1,500 scans of less time-critical areas around the machine, such as electrical rooms.

“The RTC360 is a workhorse,” Rick says. “I’ve run scanners for a long time, and I don’t know of any other brand that I would be confident operating for 72 hours straight.”

Comprehensive, accurate digital twin provides tremendous value

Within 20 days after scanning, RZA produced a comprehensive as-built database of the paper machine in Leica TruView, a software for intuitively sharing point cloud data, as well as IMP and E57 scan files. This gave Sappi a full digital representation, down to the millimeter, of the entire paper machine. With the use of Leica scanners, RZA was able to offer a scan accuracy of 2 millimeters. The detail and accuracy of the resulting point cloud data enabled Sappi to ensure that prefabricated parts for the rebuild were a perfect fit once they arrived on site. The rebuild project was completed quickly and seamlessly with no rework required.

“RZA was able to deliver a quality product on short notice in a way I wasn’t sure was possible,” says Zachary. “Since then, RZA has helped us in numerous ways—joining meetings to ensure proper orientation of the point cloud, delivering copies of the point cloud no matter the situation, cleaning up any ‘ghosting’ in the scans on short notice, and explaining the process in the simplest terms, just to name a few.

“I would highly recommend RZA and the Leica scanners for a high-quality product in a timely manner.”

Technology + Experience Drives Success

With every new project, Rick and his team at RZA Technologies gain valuable experience that they’re able to apply to bring even more value to their clients.

“If we hadn’t ever run a shutdown or a project of that size before, there are things we wouldn’t have been able to anticipate,” Rick explains. “But we have a tried and trusted workflow that is completely scalable.

“When we get a complex project with time constraints, we don’t have to reinvent the wheel,” he adds. “We approach it the same way we’ve done our other jobs—and just do it a little faster.”