Automotive

The pace of change is accelerating. Knowing what you have in your plant today is key to implementing smarter processes and staying ahead of rapidly shortening product lifecycles and supply chain disruptions.

COMMON CHALLENGES

Shutdowns & Retooling

More frequent retooling leads to increased shutdowns. Every minute a plant is shut down costs money.

Information Gaps

Model changeovers, maintenance issues and emergency situations require immediate access to information that reflects the reality of the plant. CAD drawings and models are often inaccurate and incomplete.

Disconnected Systems

As automobiles become increasingly connected and data-driven, manufacturing complexity increases. Missing or inaccurate data restricts the full insight into plant operations that is crucial for maximizing agility and efficiency.

BENEFITS OF LASER SCANNING REALITY CAPTURE

Efficient Design

& Implementation

Access to current, measurable data with clear visualizations enables more efficient use of existing assets, minimizes downtime, and fast-tracks upgrades and renovations.

Accurate &

Complete Data

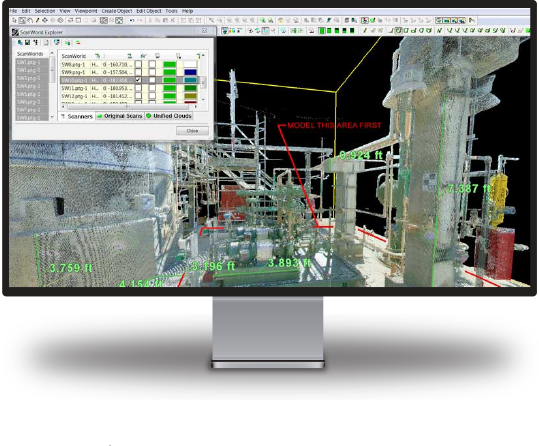

Laser scanning quickly and safely captures every detail of the facility down to the bolts in the floor. The resulting point cloud data provides crucial insight for designers, engineers, operations & maintenance, and even offsite vendors looking to provide the perfect fit on new tooling installations.

Seamless

Collaboration

With laser scanning reality capture at its core, your digital twin becomes an information hub that supports every facet of your manufacturing operation, enabling you to minimize costs and maximize efficiency.

DISCOVER INSIGHTS

LASER SCANNING SOLUTIONS

Whether your data capture priorities are distance, speed, accuracy, flexibility, ease of use, autonomous operation, or all of the above, Leica Geosystems provides industry-leading solutions that simplify your digital transformation.

SOFTWARE SOLUTIONS

The security, accessibility and usability of your laser scanning reality capture data is crucial to maximizing operational efficiency and obtaining the best return on your investment. Leica Geosystems software leads the industry for transforming vast amounts of digital data into intuitive yet powerful information assets.

Seamless Integration

Our solutions are compatible with the most popular third-party software, making it easy to integrate reality capture into your existing workflows.