"3D laser scanning technology offers unmatched accuracy and precision, capturing data with millimeter-level detail. This capability is crucial for detecting even the slightest deviations or damage in tank structures.” —Travis Sachs, president, 3DS Technologies Inc.

In the world of industrial operations, tank management is a critical aspect that can significantly impact safety, efficiency, and financial outcomes. Industries ranging from oil and gas to food processing, automotive manufacturing, and even roofing rely heavily on large tanks and silos for storage and processing. The traditional approach to tank management has often been reactive, addressing issues only after they arise.

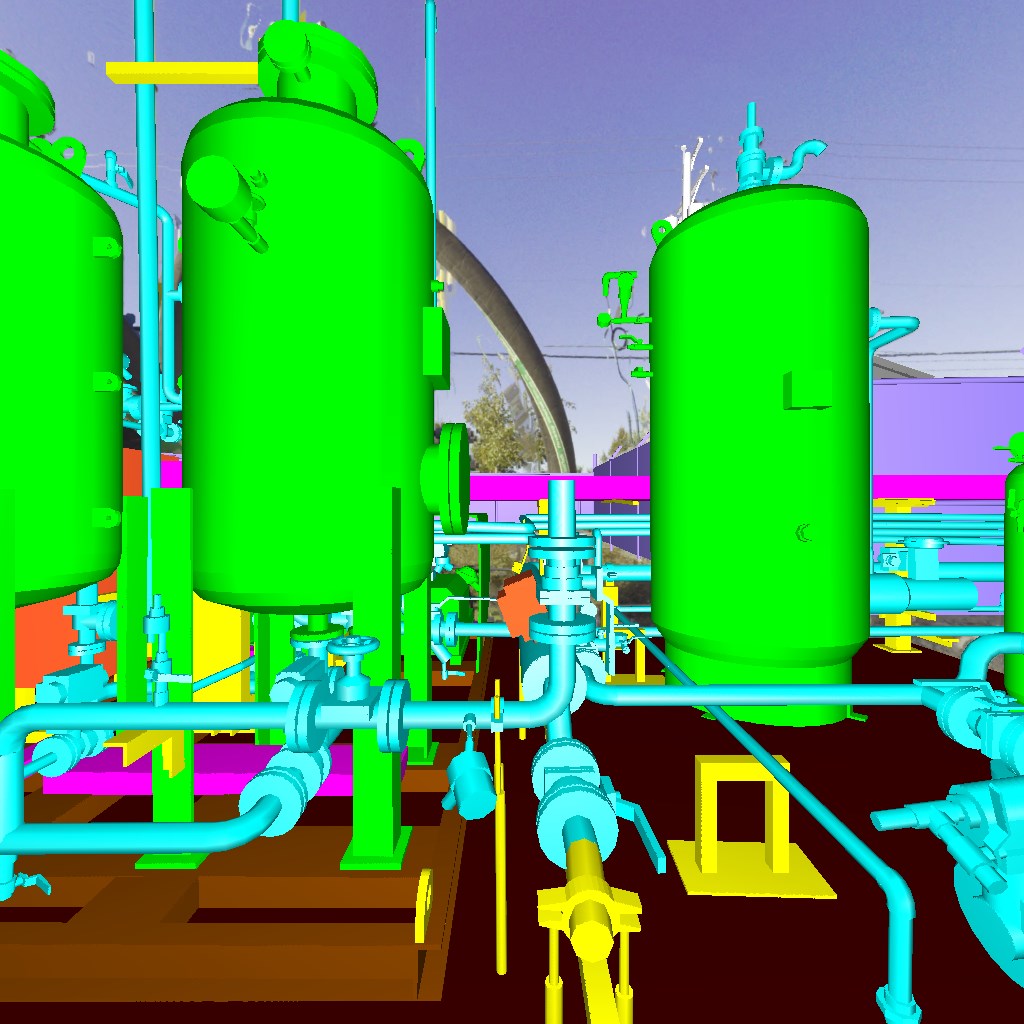

Increasingly, however, facilities are shifting toward a proactive tank monitoring strategy using advanced 3D laser scanning technology.

The Risks of Reactive Monitoring

In many industries, tank monitoring is still conducted through visual inspections and occasional manual measurements. According to Travis Sachs, president of the 3D laser scanning services firm 3DS Technologies based in Guelph, Ontario, Canada, this approach is “an accident waiting to happen.” Visual inspections may not reveal subtle deformations, bulging, or settling that could indicate structural weaknesses. When issues are only addressed after a failure, companies face significant risks, including costly repairs, operational downtime, and potential safety hazards.

For example, Sachs recounts incidents where tanks have failed, leading to product spills and extensive cleanup efforts. In one case, a critical gas tank ruptured and was out of service for a year before the situation could be resolved. In another situation, a grain tank burst, causing a significant spill of its contents.

These incidents not only disrupt operations but also attract regulatory scrutiny and insurance investigations, further compounding the financial and reputational damage.

The Proactive Approach with 3D Laser Scanning

Proactive tank monitoring involves regular and precise assessments. Using 3D laser scanning technology for tank monitoring allows for the creation of a detailed baseline of the tank’s condition, which can be compared against future scans to detect any changes.

The process is fast and easy. First, a detailed scan of the tank is conducted, capturing precise measurements and identifying any anomalies. Scans are captured without disrupting operations and can be completed in minutes using Leica laser scanning technology. This data is then analyzed and compiled into a comprehensive report, providing actionable insights for maintenance and management. The entire process can be completed within 24 hours. The deliverables typically include a detailed assessment of the tank’s condition, along with recommendations for any necessary repairs or maintenance.

RELATED: The Technology Secret Behind 3DS Technologies’ Outstanding Laser Scanning Services >

Depending on the needs of the manufacturing operation, the process is usually repeated semiannually or quarterly for an effective monitoring program.

Laser Scanning Advantages for Tank Monitoring

Laser scanning offers several advantages over other monitoring methods:

- Accuracy and Detail: The technology captures data with millimeter precision, allowing for the detection of even minor deformations or shifts that are invisible to the naked eye.

- Non-Intrusive Monitoring: Scans can be conducted without disrupting operations, making it feasible to integrate regular monitoring into existing maintenance schedules.

- Comprehensive Reporting: The data collected provides a comprehensive view of the tank’s condition, enabling informed decision-making and timely interventions.

Sachs highlights a case where proactive monitoring detected a 7mm shift in a silo within a week, allowing the company to reinforce the structure before it could fail. This early intervention prevented potentially catastrophic outcomes and demonstrated the value of regular monitoring.

Financial and Safety Benefits

One of the most compelling arguments for proactive monitoring is the cost savings. Sachs suggests that the cost of regular inspections is a fraction of the potential losses incurred from a tank failure. For instance, a scan-based inspection with comprehensive reporting typically costs less than $2,000 outsourced to a scanning service provider, while the financial impact of a major incident could run into hundreds of thousands or even millions of dollars. If the tank scanning work is handled in-house, the laser scanner can also be used for other applications that bring value to the overall operation, quickly compounding the return on investment.

Beyond financial considerations, proactive monitoring enhances safety by ensuring that tanks are structurally sound, thereby protecting workers and the surrounding environment. This approach aligns with a growing emphasis on corporate responsibility and regulatory compliance.

A Strategic Shift

The transition from reactive to proactive tank monitoring represents a strategic shift that can safeguard industrial operations against unforeseen failures. By leveraging advanced 3D laser scanning technology, companies can not only prevent costly incidents but also optimize their maintenance practices and enhance overall safety. As industries continue to evolve, embracing proactive monitoring will be essential for maintaining competitive advantage and operational resilience.

Investing in proactive tank monitoring is not just a cost-saving measure—it’s a commitment to safety, efficiency, and innovation in industrial operations.

To explore digital solutions that meet your needs, get in touch with one of our reality capture specialists.