We knew that as we continued to upgrade the facility, we would need accurate, complete documentation to do so effectively. That led us to laser scanning.

When Mabel White Holmes developed and introduced the first “JIFFY” prepared baking mix to homemakers in the spring of 1930 through the family business, Chelsea Milling Co. in Chelsea, MI, she couldn’t possibly have envisioned a time when a million and a half boxes of mix per day wouldn’t be enough to meet demand.

Location

Chelsea, Michigan, USA

Benton Harbor, Michigan, USA

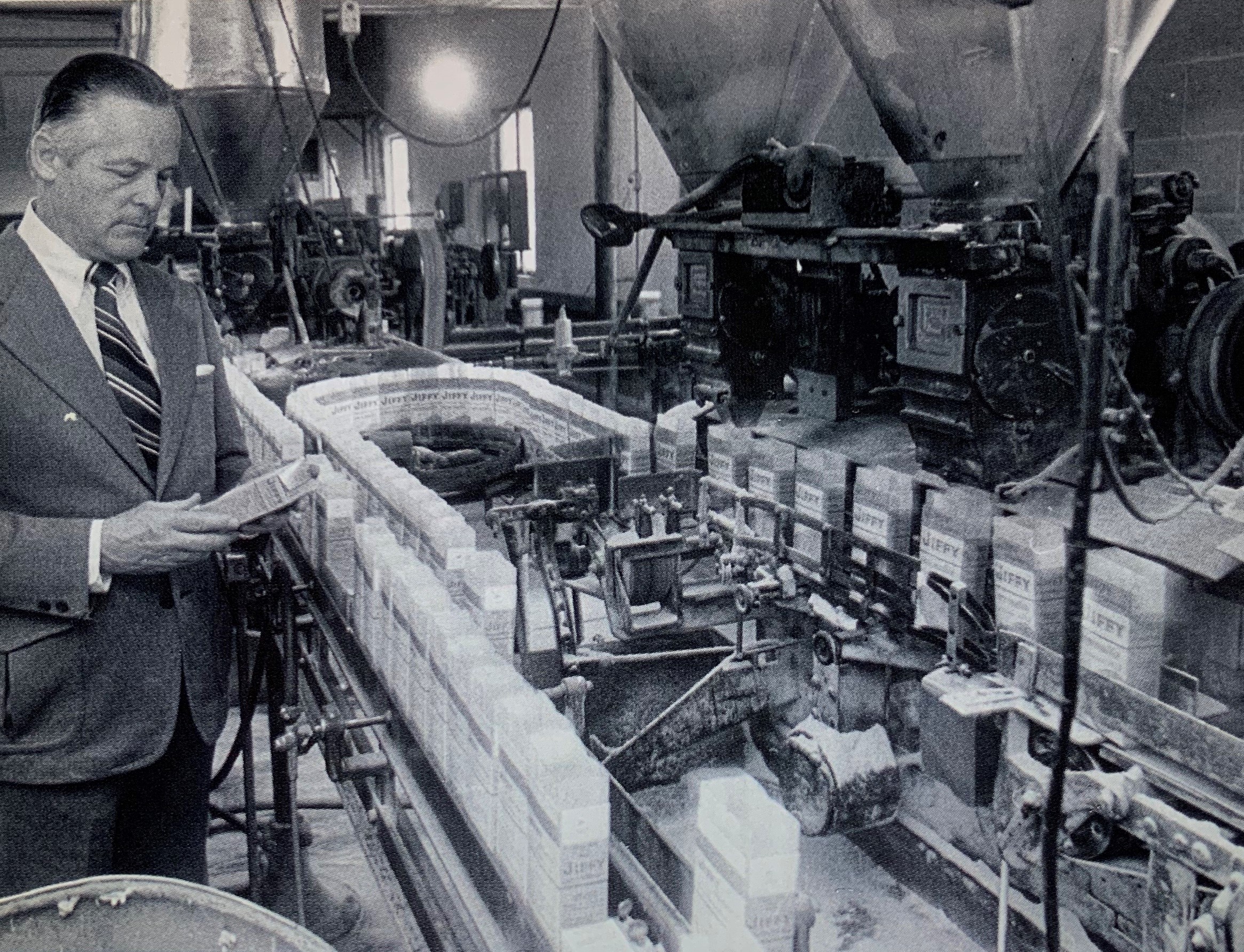

Today, “JIFFY” Mixes remains a family-owned company dedicated to serving the market with retail prepared baking mixes, institutional mixes and food service. The company takes pride in its rich history while continuing to embrace innovation. From its early beginnings as a flour mill in the late 1800s, to its first foray into packaging and package manufacturing in the 1930s using pneumatic machines to produce its signature little blue box, and on into more recent modernization projects, “JIFFY” Mixes has held a long-term view committed to manufacturing excellence, employee well-being and sustainable growth.

This vision is the guiding force in technology decisions. While the company has always been technologically advanced, the owners made a conscious decision early on not to displace workers with technology. They have installed computerized systems and automated machines to meet the increasing demand and stringent quality standards for their popular corn muffin, cake, pie crust and flavored muffin mixes, all with an eye toward safeguarding jobs for their current employees, which they view as an extended part of the family. But as more workers began approaching retirement age, fourth-generation owner and CEO Howdy Holmes and other company leaders knew that continued growth would require more agility.

In 2015, the company launched a multi-year $35 million capital improvement project that involved installing several bulk ingredient silos, constructing some small buildings and adding a new mixing department. The project also included an upgrade to flour transfer systems, enabling it to increase the transfer rate from 10,000 to 35,000 pounds per hour. The paper drawings of the plant from the late 1960s and early 1970s gave the engineers enough to move the project forward, but they also recognized the documentation process had to change.

An initiative to upgrade the retail packaging operation in 2018 gave them new incentive. “The paper drawings were unreliable,” said Director of Manufacturing Scott Denny. “We knew that as we continued to upgrade the facility, we would need accurate, complete documentation to do so effectively. That led us to laser scanning.”

In any industrial plant project, but especially in food processing, both accuracy and speed are paramount. ... The combination of experience and the right technology is invaluable.

Accurate, Complete Documentation from a Distance

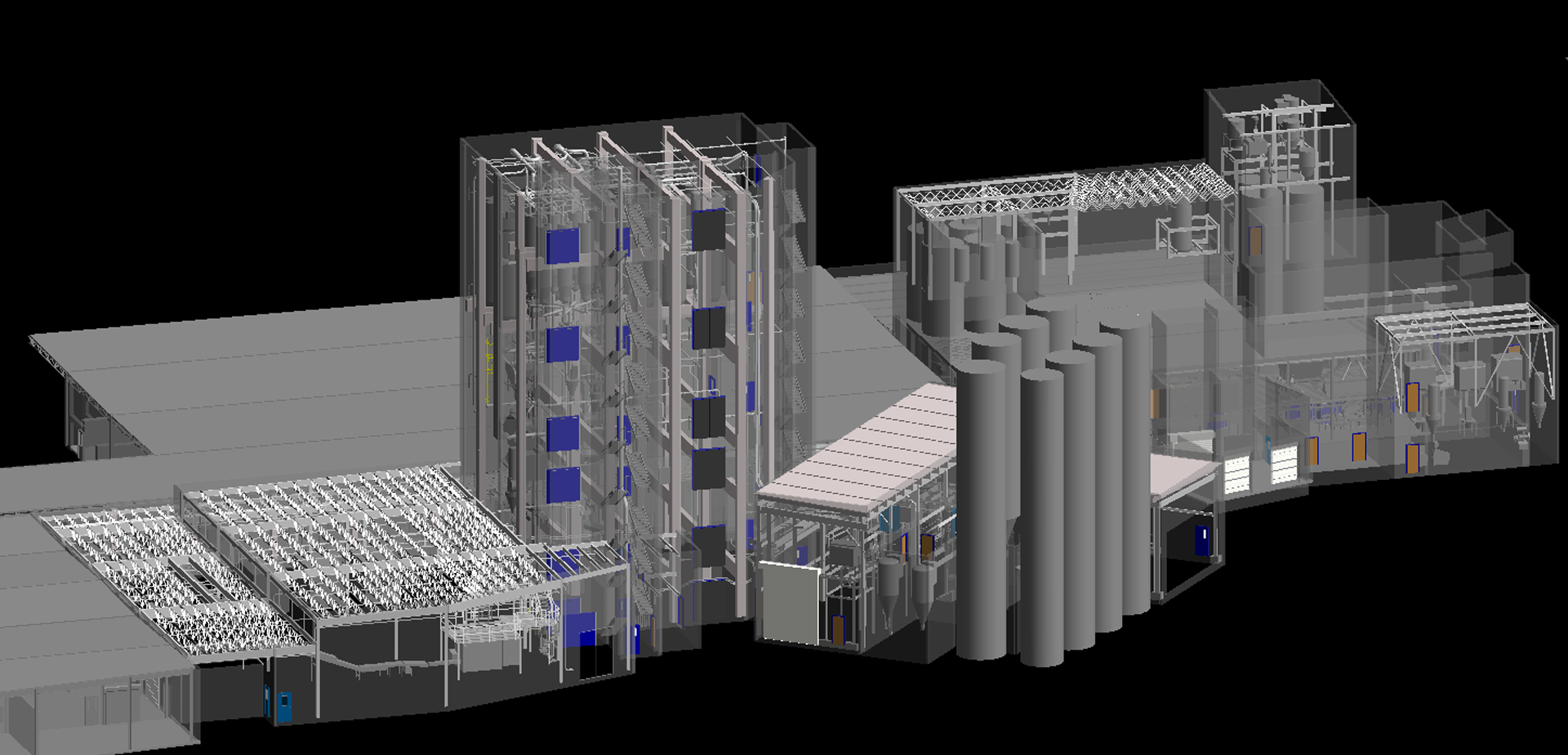

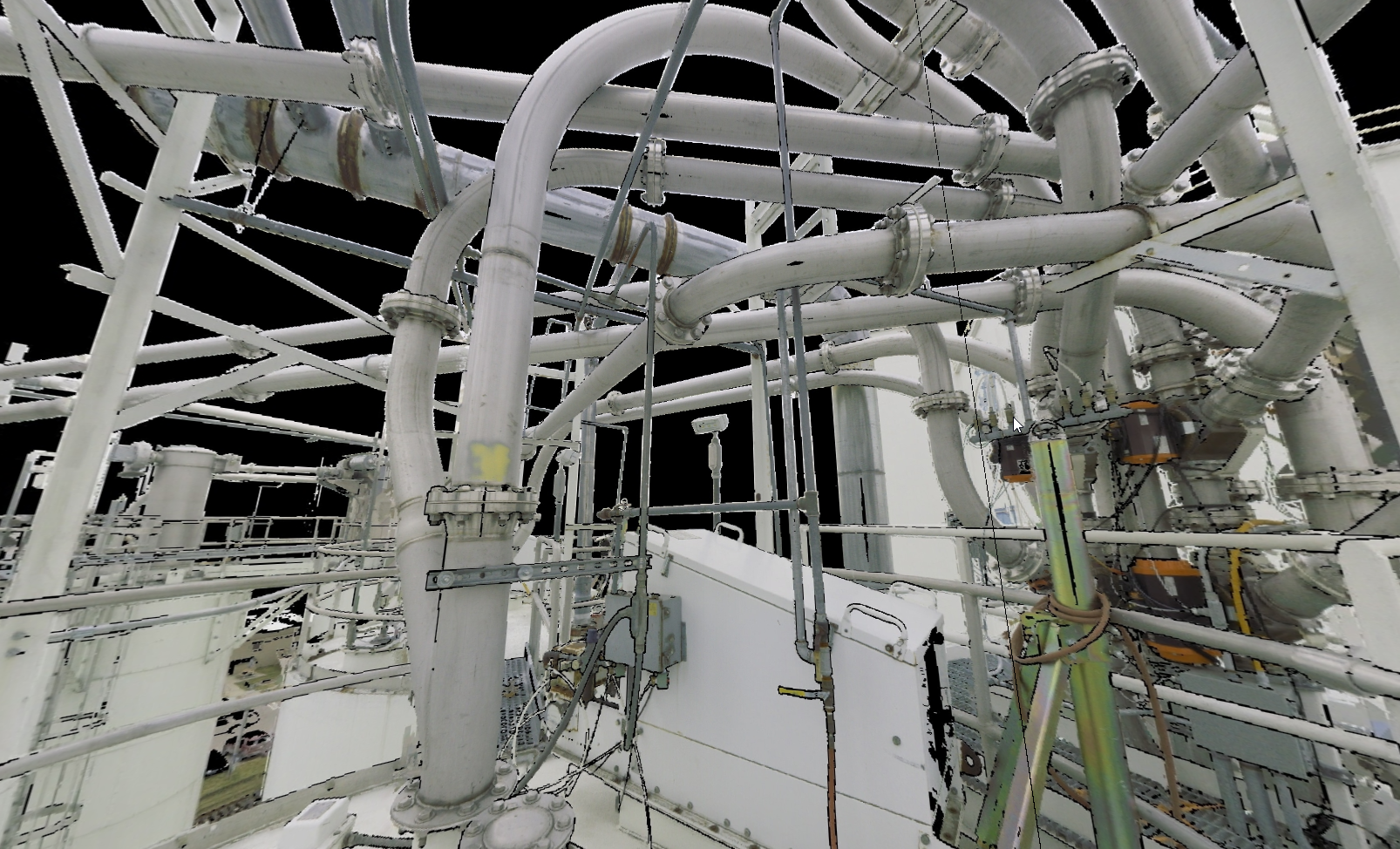

A 3D laser scanner measures and records x,y,z points of whatever it sees and “freezes” the site in time in its current form. The resulting data, in the form of a point cloud, can then be brought into CAD or 3D software and used to develop extremely accurate existing condition drawings and models. The point cloud data from a laser scanner is so complete that it provides details all the way down to the bolt pattern on steel pipe fittings, providing the insight needed to keep a plant at peak performance.

Unlike traditional plant documentation methods, which require a team of people with clipboards and tape measures climbing ladders and balancing on catwalks, laser scanning is a noninvasive technology that captures measurements safely from a distance without affecting line production or introducing potential contamination. Comprehensive measurement data can be captured by a single operator, further minimizing the impact on plant operations and the need for clearance requirements.

“One of the benefits that really stood out to us was the ability to capture accurate documentation on the entire plant without affecting production,” says “JIFFY” Mixes Project Engineer Rick Rabideaux. “It was exactly what we needed.”

The company first focused on its retail packaging operation to determine whether an upgrade would be feasible. The data was so compelling that Denny and Rabideaux decided a full digital twin was the next logical step.

In 2019, “JIFFY” Mixes launched a multi-year digitalization project with Wightman based in Benton Harbor, MI, a full-service consulting firm that is a recognized leader in as-built data capture using 3D laser scanning. Beginning with a Leica ScanStation P40, a rugged professional-grade laser scanner that provides fast, full-dome, survey-grade scanning at a long range, Michael Pfaff, Wightman’s reality capture practice area leader, systematically began capturing accurate as-is data throughout the plant that would enable all future design drawings to be based on real-world conditions.

More recently, Pfaff and his team have begun using the newest laser scanning technology, a high-speed Leica RTC360 that captures comprehensive data in seconds. The faster speed streamlines data capture onsite. Combining the hardware with powerful point cloud processing and management software such as Leica Cyclone and REGISTER 360 accelerates the turnaround of deliverables.

“In any industrial plant project, but especially in food processing, both accuracy and speed are paramount,” Pfaff says. “We’ve honed our expertise and made investments in our people and technology that enable our clients to move projects forward with confidence, knowing they’ll have access to the data they need when they need it. The combination of experience and the right technology is invaluable.”

Having the data will give us the agility in the future to be able to quickly retool and move lines around. ... There’s a lot of potential to apply the data moving forward.

The Value of a Digital Twin

Pfaff, who has what he describes “a feverish addiction to technology,” believes laser scanning is a crucial first step for every food processing plant. “Once you’ve captured the data, you have a complete, comprehensive dataset that you can go back into at any time and continue to pull information from it,” he says. “Instead of models and drawings that are outdated as soon as they’re complete, you have a living, breathing digital twin of your facility that you can continue to use over time for operations and maintenance, or future renovation projects.”

But technology alone isn’t enough. Using the data is where the real value of a digital twin comes into play. A big part of Wightman’s service is guiding clients how to understand, manage and apply the data effectively. Using tools like Leica TruView enables Wightman to provide remote access to stakeholders to view and annotate the laser scan dataset. “TruView is nice because it’s a web interface,” he says. “With all the tools available in the viewer, now we don’t have to model everything. We can focus on just the critical elements. That capability provides a significant savings in time and cost.” (RELATED: Explore a 360-degree digital dataset in TruView Cloud.)

Having a technology champion within the plant is also key to extracting the full value from point cloud data. At “JIFFY” Mixes, that champion is Rabideaux. “Right now, the power of the 3D digital dataset is in implementing our packaging equipment upgrade project quickly, safely and with minimal rework,” Rabideaux says. “We’re sharing point clouds and models with contractors to prefabricate components offsite. Knowing they’ll be an exact fit when we bring them in is a huge savings.

“Having the data will also give us the agility in the future to be able to quickly retool and move lines around,” he adds. “It will make ongoing inspection and maintenance safer and easier. We’re also exploring the use of virtual reality and augmented reality to apply to various applications in the plant design. There’s a lot of potential to apply the data moving forward. The company owners have been very forward-thinking in allowing the engineers to be innovative and making the investments to do it right.”

Although the signature blue box of “JIFFY” Mixes has remained relatively unchanged since its introduction 90 years ago, the company’s ability to adapt and innovate its manufacturing approach has positioned the company for continued success well into the future.

“We’re committed to providing the best products that we possibly we can, and that kind of layers deep into how you manufacture and how reliable you can be,” says Howard Holmes, Executive VP and COO, in a recent company video. “It’s taken a lot to get here. We’ve had to truly look at the horizon, the long term, and commit ourselves to sustainable growth—putting our employees first because the reality is we are a family business, and everybody in this business is part of the family.”

The digital twin of the “JIFFY” Mixes manufacturing operations is a fitting tribute to Mabel Holmes’ legacy.