"With laser scanning, energy projects are completed significantly faster, and it virtually eliminates rework."

Location

Calgary, Alberta, Canada

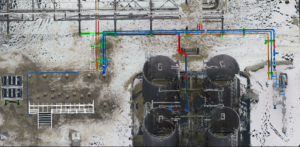

Building or retrofitting an energy plant has gotten much easier in recent years thanks to advances in digitization. Installers no longer need to wait until piping and equipment shows up onsite and pull tape or string lines to see what adjustments are needed to fit it all into place. Instead, they can immediately begin the installation with confidence that everything will be a perfect fit—if high-quality laser scanning has been used to capture an as-built model, that is.

Zachary McNeil, owner of Proport Pipefitting Inc., provides laser scanning, design and drafting services for engineering and construction firms throughout the Calgary region in Canada. With laser scanning, he quickly captures as-built conditions and rapidly delivers 2D and 3D models and flythroughs that enable accurate fabrication and precise installation of even tight-fitting, complex piping work. “The cost savings are huge,” he says. “When equipment shows up, the piping is already fabricated and ready to bolt up. It fits every single time.”

McNeil recently spoke with Oil & Gas IQ, where he provided insights on the advantages of laser scanning and the trends that he sees emerging in the industry.