"With predictable maintenance activities, you can increase production volume … you increase revenue and you decrease costs." —Dominik Baumgarten, Grace ANYmal Deployment and Operation

Dealing with unplanned maintenance in an industrial plant can be costly in downtime and repairs. But gaining enough insight on your operations to develop a successful preventive maintenance schedule can be challenging, especially if your plant runs a 24/7 production cycle. You need to be able to capture data on the facility regularly without putting people in harm’s way.

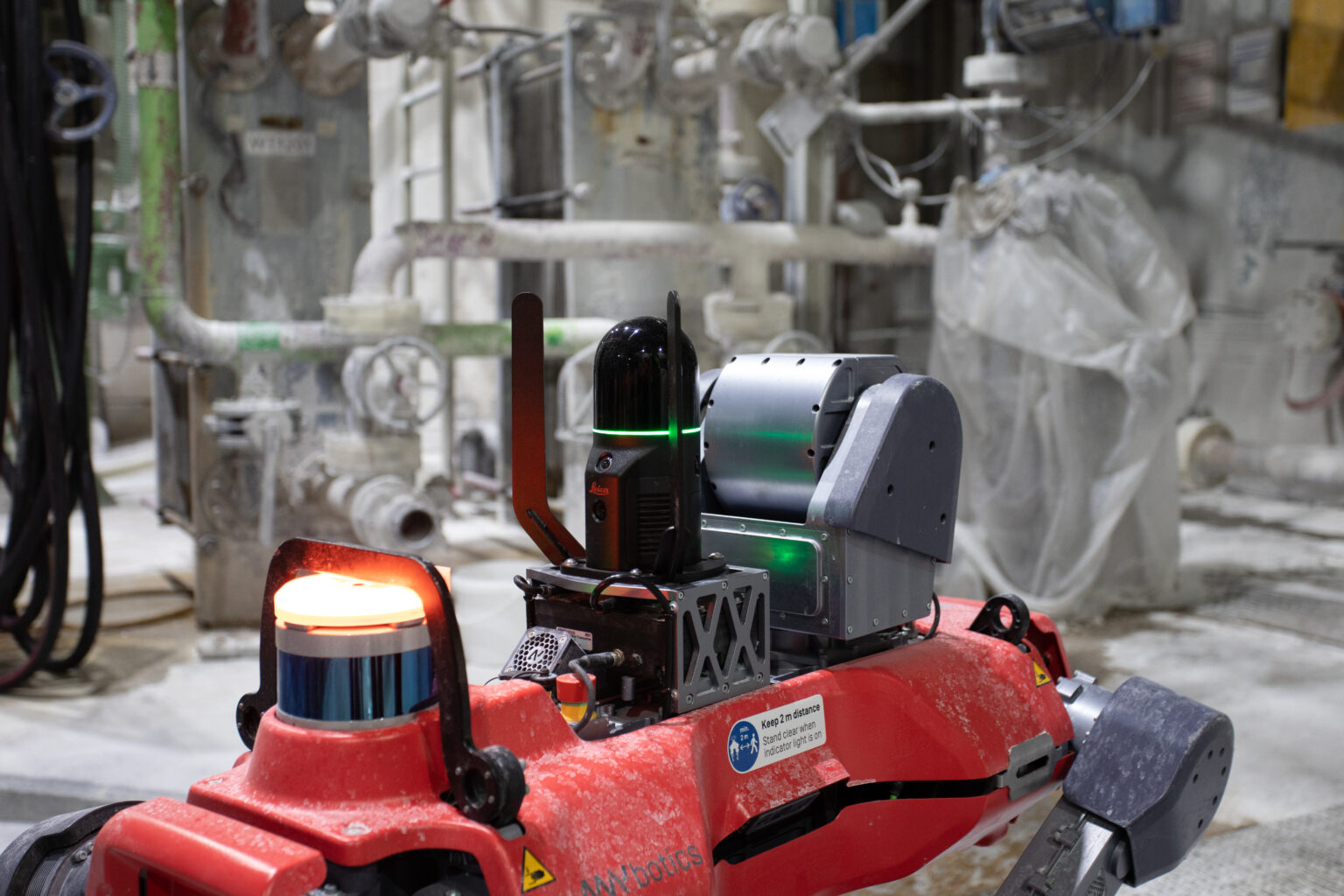

W.R. Grace implemented an innovative solution for its Düren Chemical plant in Germany. Recognizing that current, accurate, and accessible documentation of plant assets is crucial, the company paired the Leica BLK ARC autonomous laser scanning module with ANYmal, a four-legged robot that navigates through environments with complete autonomy.

BLK ARC integrates an enclosed dual-axis LiDAR scanner with an advanced vision system comprising three cameras that capture the surrounding environment to track 3D movement and to colorize point clouds. A forward-facing camera captures geo-located images within the point cloud. Data from BLK ARC is sent to the robotic carrier for better autonomous decision-making.

Managers can remotely chart the path of the scan with existing drawings and BIM models, and the robot will navigate as directed and scan autonomously. The managers can then use the 3D point cloud of the current state of the facility to make more informed decisions on operational improvements.

W.R. Grace estimates that this approach is seven times more cost efficient than outsourcing the scanning. More scans can be completed with less human intervention and greater speed.

The company is also using ultrasound and thermal sensors on ANYmal to monitor electric motors, pumps, and compressors, as well as visual inspection sensors for equipment supervision and water level measurement. The full system provides significant advantages.

“I think the benefits in the future will be huge, because having a fully automatic robot running around in a facility like this here is awesome,” says Dominik Baumgarten, Grace ANYmal Deployment and Operation. “We can use it all around the clock. It has a huge impact as it makes the unpredicted or unnoticed maintenance failures predictable. With predictable maintenance activities, you can increase production volume … you increase revenue and you decrease costs.”

You can read more on the ANYbotics blog.