The importance of 3D laser scanning to achieve fast, accurate plant as-built documentation for construction projects/retrofits and the creation of a digital twin is well established. However, ensuring efficient and accurate work requires using the right data capture tools. Two laser scanners, the Leica RTC360 and the next-generation Leica BLK360, are popular choices among industrial plant documentation professionals. Which one is better?

Leica RTC360 and Next-Generation BLK360 at a Glance

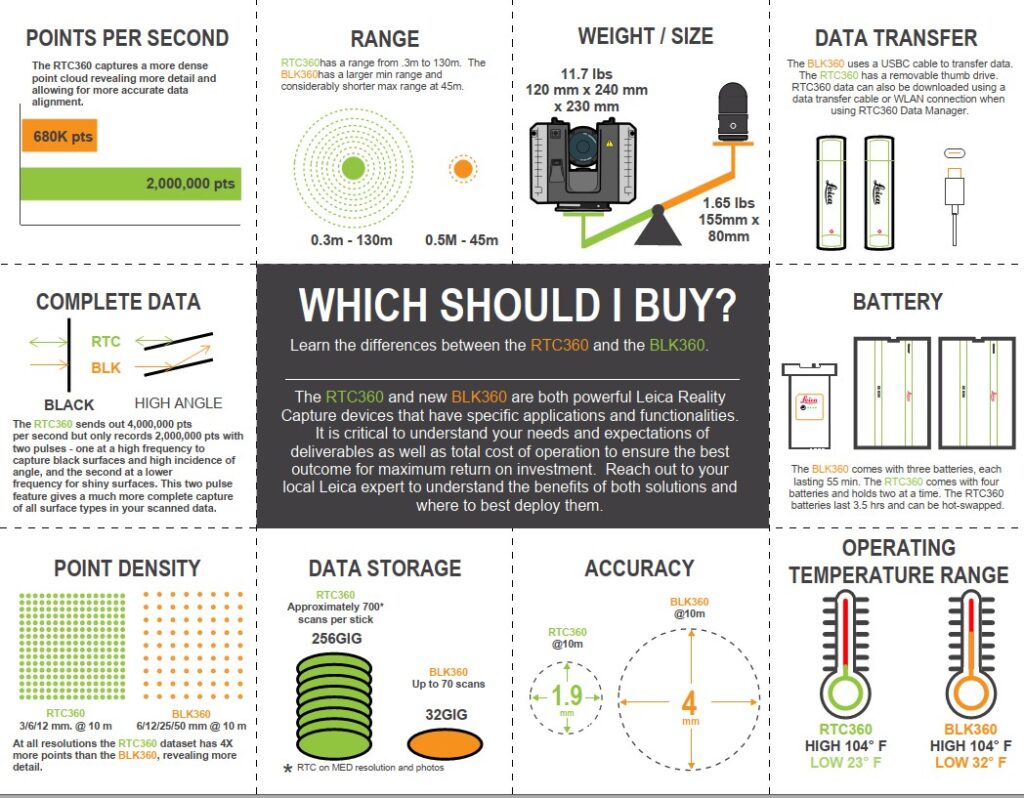

The Leica RTC360 3D laser scanner is a highly accurate, reliable, and portable hardware and software solution. With a capture rate of up to 2 million points per second and an advanced HDR imaging system, the scanner can complete a full black-and-white scan in as little as 26 seconds and colored 3D point clouds in under two minutes. The scanner automatically pre-registers point cloud data in the field to allow you to quickly conduct quality control checks, improve productivity, and make better-informed decisions on site.

The next-generation BLK360 imaging laser scanner is a high-speed option that is well suited for smaller projects and confined spaces. While not as accurate as the RTC360, it is still capable of producing high-quality, detailed scans. The BLK360 is also portable, easy to use, and offers fast data processing, capturing a full scan with spherical images in only 20 seconds. The imagery capture with the BLK360 is outstanding.

The most obvious differences between the two scanners are in price and size, with the next-generation BLK360 an attractive option for cost-conscious operators looking for laser scanning capabilities in a small form factor. But selecting the right scanner isn’t always so straightforward.

Following is a review of five key capabilities, advantages, and limitations of both technologies to help you make an informed decision.

can complete a full black-and-white scan in as little as 26 seconds and colored 3D point clouds in under two minutes.

1. Accuracy and Range

The RTC360 captures high-resolution data with millimeter accuracy, making it ideal for projects that require precise measurements such as piping as-builts, multilevel machinery documentation, and floor flatness analysis. However, the BLK360 is not far behind and can capture data with sub-centimeter accuracy, making it a suitable option for as-built data capture in many industrial plant applications.

Two considerations that can help you quickly drill down to the right technology are the level of accuracy and the range requirements needed for your project or digital twin documentation.

The RTC360, a professional-grade scanner, is typically the scanner of choice for projects that require higher accuracies, longer ranges, and more diverse analysis. On the other end, the BLK360 is a great entry-level scanner that allows you to quickly gather data. It’s ideal for smaller projects that require less range and a little less accuracy. The BLK360 is also a great way to start to understand the workflows and deliverables, with the potential to work up to a more professional-grade laser scanner.

2. Ease of Use

Both laser scanners are user-friendly and can be operated by anyone at any skill level. Training typically takes less than five minutes. Both scanners have an intuitive interface and streamlined workflow that can help users save time and increase productivity. However, the BLK360 is a more compact and lightweight scanner that is easy to carry around and deploy on site. If ease of use is the primary consideration, the next-generation BLK360 offers an advantage.

However, it’s important to remember that the real value is in the deliverables that can be created from the point cloud data captured with these tools. Understanding the tolerances and specifications you need is crucial, along with the workflows and deliverables.

3. Speed

The BLK360 is faster than the RTC360 when it comes to capturing a single scan. However, this does not necessarily translate into faster project completion as the BLK360 may require multiple setups to capture all the necessary data. More setups can lead to additional time spent on data processing and a higher total cost of operation. In contrast, the RTC360 can cover larger areas quickly with fewer setups, resulting in faster project completion and reduced operational costs.

Total cost of operation is an important consideration when exploring any technology. While the BLK360 is a faster scanner, it might be a little more expensive to deploy in a larger space. Data storage, data transfer, battery life, and the ability to hot swap the batteries also factor into the total operating cost.

“The next-generation BLK360 works great for our project managers to go out and do some basic scanning of VFD rooms, small electrical buildings, switchgear systems, small truck loading racks, additive tank areas and trap sites. When we need more range, multiple scans that tie together easily, and high performance in direct sunlight, we use the RTC360.” —Russell Whitehead, laser scanning and survey department lead, ESDC Engineering Inc.

4. Versatility

Both the RTC360 and new BLK360 are versatile and can be used for various construction projects. The BLK360 is ideal for projects in small spaces that require fewer scans. If you work in a wide range of areas and spaces, the RTC360 might be a better choice. It can easily handle large and complex projects due to its high accuracy and fast data capture speed. It can also capture accurate measurements of buildings, complex machinery, and other structures.

5. Operating Environment

Laser scanning for industrial plants often requires working in challenging environmental conditions. The RTC360 laser scanner is designed to operate in a wide range of environments and can withstand inclement weather. Operators have successfully taken the laser scanner in the rain and snow and in very hot and cold conditions. The optics are enclosed on the RTC360, so dust and moisture aren’t an issue. It also has a filtering system that will clean the data set when you do have to run the scanner in rain or snow. It’s a tremendously rugged scanner that can handle a lot of different weather conditions.

In comparison, the BLK360 is more conservative and has more environmental constraints.

The Verdict

Based on the analysis above, each laser scanner has its own strengths and limitations. In general, the Leica RTC360 is often considered the best option for large and complex projects that require high accuracy and fast data capture speed. The next-generation BLK360 can be a suitable choice for projects with less square footage.

For many plants, the best approach is to have both laser scanners available for use. Supplementing the workhorse capabilities of the RTC360 with a next-generation BLK360 as a fill-in will optimize scalability and provide the best fit-for-purpose for any application where you need current, accurate, and comprehensive measurement data.

To explore laser scanning solutions and discuss your needs with a industrial plant solutions specialist, contact us.