"With a full facility scan, every individual project is scanned after it’s completed and incorporated into a controlled model. Every contractor is working off the same info, and our clients know they have accurate as-builts." —Russell Whitehead, Laser Scanning and Survey Department Lead at ESDC Engineering Inc.

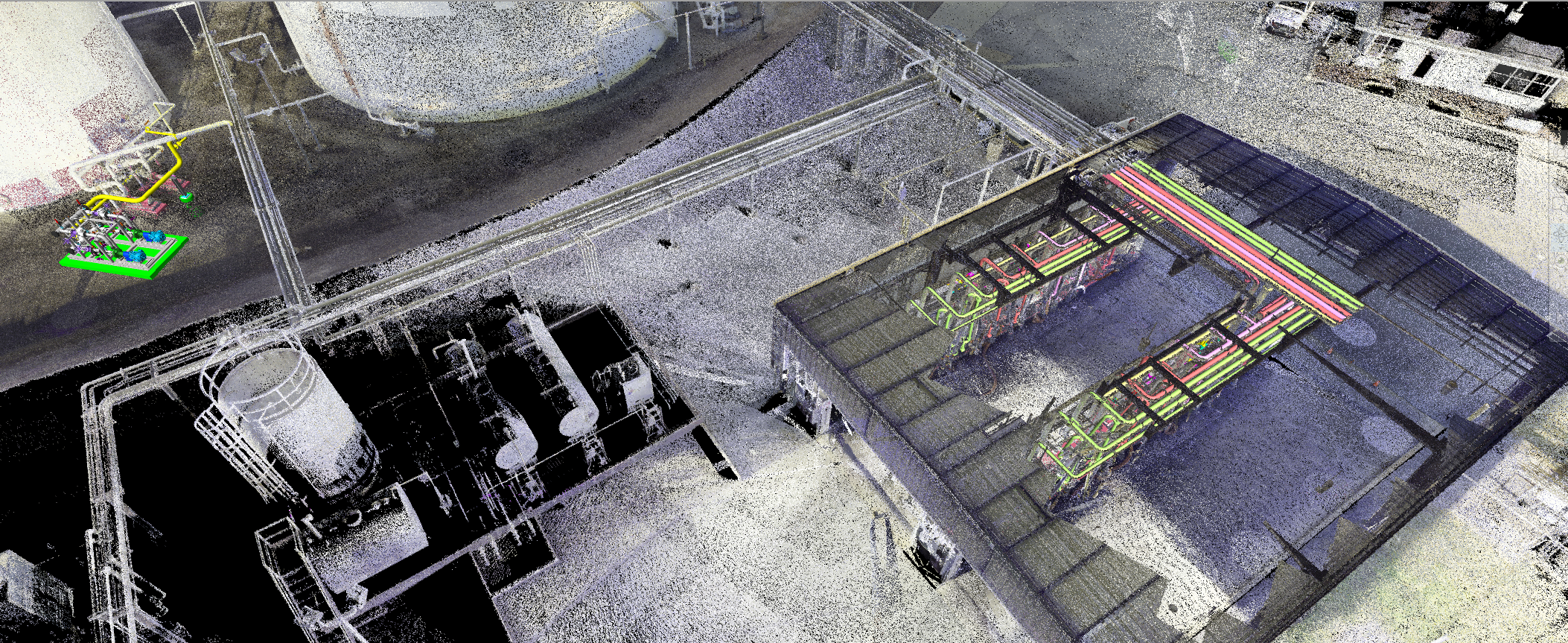

- ESDC Engineering Inc. produces high-quality 3D plant documentation that gives clients unprecedented insight into the as-built status of their operations.

- The full-service engineering firm uses cutting-edge laser scanning hardware and software along with a lean process to ensure a timely delivery of accurate, detailed results.

- The evolution in data management and storage enables energy companies to easily handle large data sets while retaining the benefits of easy access to a complete digital twin of their facility.

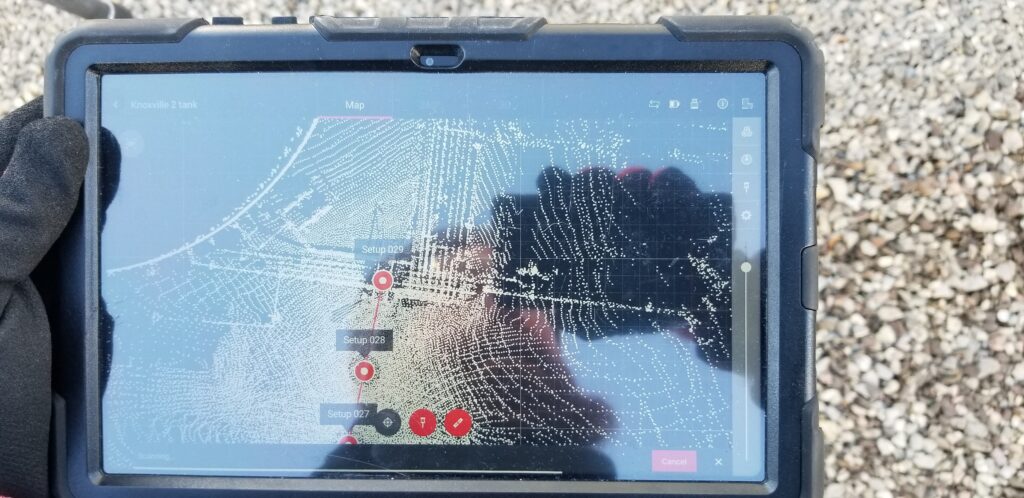

- Technology advances such as the tripod-based Leica RTC360 laser scanner and handheld Leica BLK2GO imaging laser scanner make it easy for industrial plants to capture their own scans to keep their as-built documentation current.

"The Leica technology works the way it is branded to work. We’ve looked into buying other laser scanners that are cheaper, but it doesn’t make sense to lose productivity just to save some money. The Leica hardware, firmware and software deliver what we need and produce a product our clients can use." —Russell Whitehead

If you use laser scanning to capture the existing conditions of your energy operations for plant expansions, retrofits, and new construction, you’re in good company.

Laser scanning is recognized as the standard in the energy industry and other industrial plant applications for quickly and accurately capturing as-built conditions to support the design and engineering process. Laser scanning ensures that new projects or modifications align precisely with existing infrastructure, minimizing errors and rework. It also provides a realistic view of the existing environment, allowing for better decision-making and resource allocation.

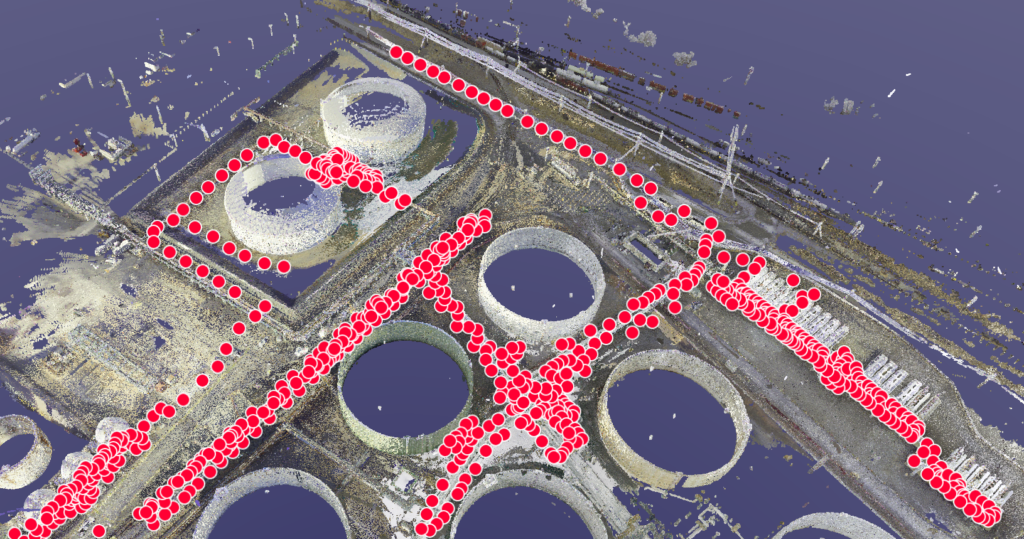

Recently, however, a new trend is gaining momentum. Instead of limiting scans to defined areas for specific projects, energy facilities and organizations increasingly are requesting laser scanning services and the creation of digital twins of full facilities.

ESDC Engineering Inc., a full-service engineering firm, is one of the companies at the forefront of this movement. The company produces high-quality 3D plant documentation that gives clients unprecedented insight into the as-built status of their operations.

Russell Whitehead, laser scanning and survey department lead at ESDC, explains, “More and more clients want full facility scans. They want to know what and where everything is in their facilities: Every section of fence line, road diking, and cable tray, and the inside and outside of every building. This along with piping sizing and location, and details such as vents, drains, reliefs, valves, supports, and tank appurtenances. And they need it done quickly. With our laser scanning approach, we can provide that service.”

High-Speed, High-Quality As-Built Data Capture

While laser scanning has been used in industrial applications for several decades, it hasn’t always been easy. Plants that experimented with the technology early on were often challenged by the complexity involved in capturing and managing the data. Recently, however, technology innovation has made 3D data sets infinitely more accessible.

By combining cutting-edge laser scanning hardware and software with a lean process, ESDC has developed a streamlined workflow that allows for efficient scanning and processing of detailed, accurate data, ensuring timely delivery of high-quality results.

ESDC uses the Leica RTC360 laser scanner, which completes a full scan in as little as 26 seconds, and the BLK360 next-generation imaging laser scanner, which captures a full scan with spherical images in only 20 seconds. Data processing software incorporating artificial intelligence and automation streamlines field-to-finish workflows. In one case, Whitehead completed 220 scans, with medium resolution point density and HDR images, in a single day.

“I can fly out in the morning and be at a site at 9:30 a.m., scan until 4:00 P.M., and fly home that night,” Whitehead says, “And I can often have the scan to my client by the end of the next business day.”

A Comprehensive Record for Maintenance and Asset Management

ESDC’s clients increasingly recognize the value of having a comprehensive digital twin that can be used for project planning, maintenance, and asset management. By capturing every detail of the energy facility through laser scanning, ESDC enables clients to access and utilize all the scan data to keep those facilities running optimally.

“With a full digital twin, you can remotely determine valve sizes and identify reusable taps,” Whitehead says. “Clients can easily open piping and instrumentation diagrams (P&IDs) and site plans for necessary information from their office. And some clients are transitioning toward a smart P&ID and modeling program in which 3D models and P&IDs are all linked, very similar to how CAD and smart plant systems work together now.”

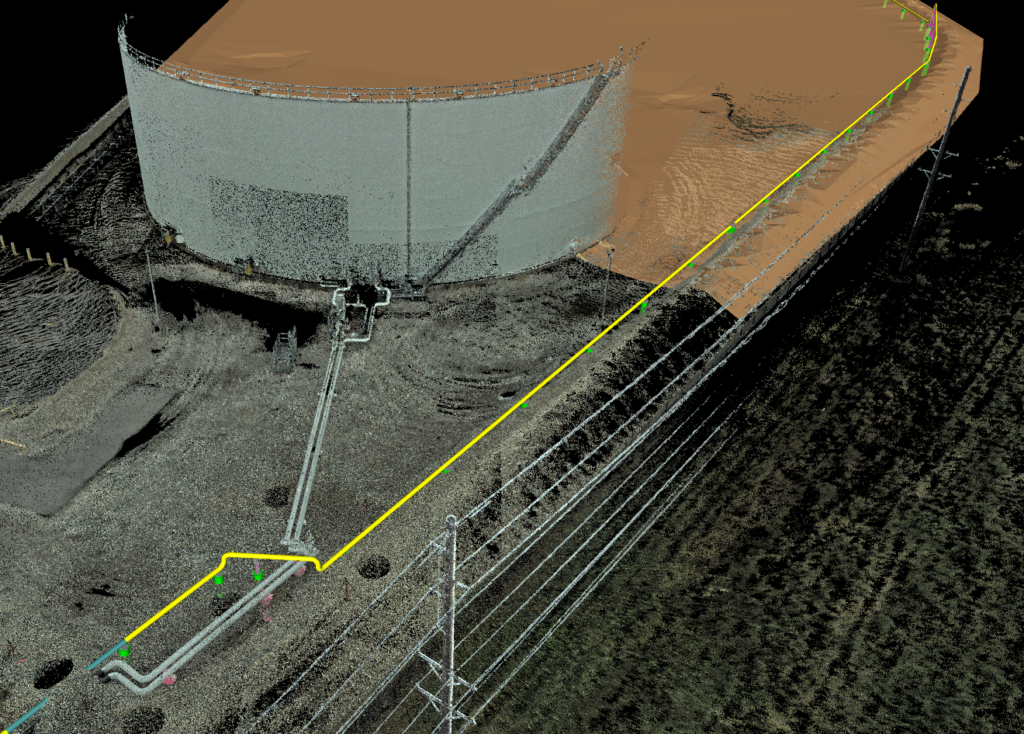

To ensure the accuracy and precision of the scan data, ESDC uses survey control to coordinate the scans, helping to ensure the scans align seamlessly and provide a true representation of the facility. This level of accuracy is essential for accurate as-built documentation and effective asset management of complex energy facilities.

“There’s a strong emphasis in the industry on ensuring coordinated accuracy of everything that’s scanned. We establish survey control points for precise positioning,” Whitehead explains. “With survey-controlled scans, I can then tell you the exact location of every foundation, pump foundation corner, and support foundation. Once we establish control points, everything in the scan aligns and has defined northings, eastings, and elevations per state plane or applied to a plant coordinate system.”

Improved Communication and Collaboration

Through full facility scanning, stakeholders can access and view the same data, enhancing communication and collaboration. With a complete 3D representation of the facility, all parties involved can visualize the project in greater detail, identify potential issues, and make informed decisions. This streamlined approach improves efficiency, reduces errors, and ultimately leads to successful project outcomes.

“Without a centralized 3D representation of the facility, contractors could all be making upgrades and changes and each working off their own facility model,” Whitehead said. “But with a full facility scan, every individual project is scanned after it’s completed and incorporated into a controlled model. Every contractor is working off the same info, and our clients know they have accurate as-builts.”

The evolution in data management and storage enables companies to easily handle large data sets while retaining the benefits of easy access to a complete digital twin of their facility.

“Laser scanning is really a very simple process,” Whitehead says. “Anyone can handle it.”

Some clients find up-to-date scans of facilities of such value that they are beginning to undertake some of the scanning themselves.

“I have clients that are exploring using the BLK2GO handheld laser scanner to pick up extra data, such as capturing the tubing on a transmitter rack,” Whitehead said. “Then they can send it to me, and I can add it to their digital twin. The scanner is handheld and easy, so they can supplement the scanning we’ve already done and keep their as-builts current.”

The Advantage of Full Facility Scanning

The trend toward full facility scanning is transforming the way the energy industry approaches project management, maintenance, and asset management.

By leveraging state-of-the-art technology, expertise, and a commitment to providing high-quality scans, companies like ESDC are paving the way for a future where digital twins are an essential tool for unlocking the full potential of facilities.