"With an accurate plant coordinate system as the foundation, you can confidently round-trip your laser scan data to a contractor for layout and verification of new installations and retrofits; use it for virtual walkthroughs for operations and maintenance; and continue to find new uses that add value." —Greg Schneider, Leica Geosystems Industrial Plant Solutions Specialist

If you’ve considered adding survey control to your plant’s in-house reality capture capabilities, you’re not alone. Forward-thinking operations are increasingly insourcing some or all of their 3D plant documentation workflows to gain more control over cost, schedule, and data management. The latest robotic total station technologies are easy to learn and use, even for operators without a survey background. In fact, thinking about it as project control instead of survey control is probably more accurate.

But is project control as simple as it sounds? Here’s an overview of what’s involved and how you can benefit.

- Set your control points. This simply involves setting up a baseline of two or three marks on the ground in the area where you will do reality capture with a laser scanner. Alternatively, you can locate existing plant control points in your reality capture project.

- Use your total station to measure the exact location of the control points and scanning project reference targets. Guided workflows and push-button operation of modern robotic total stations makes this step easy.

- Record the data. Your total station can complete this step for you almost automatically with its robotic functionality and easy to use applications

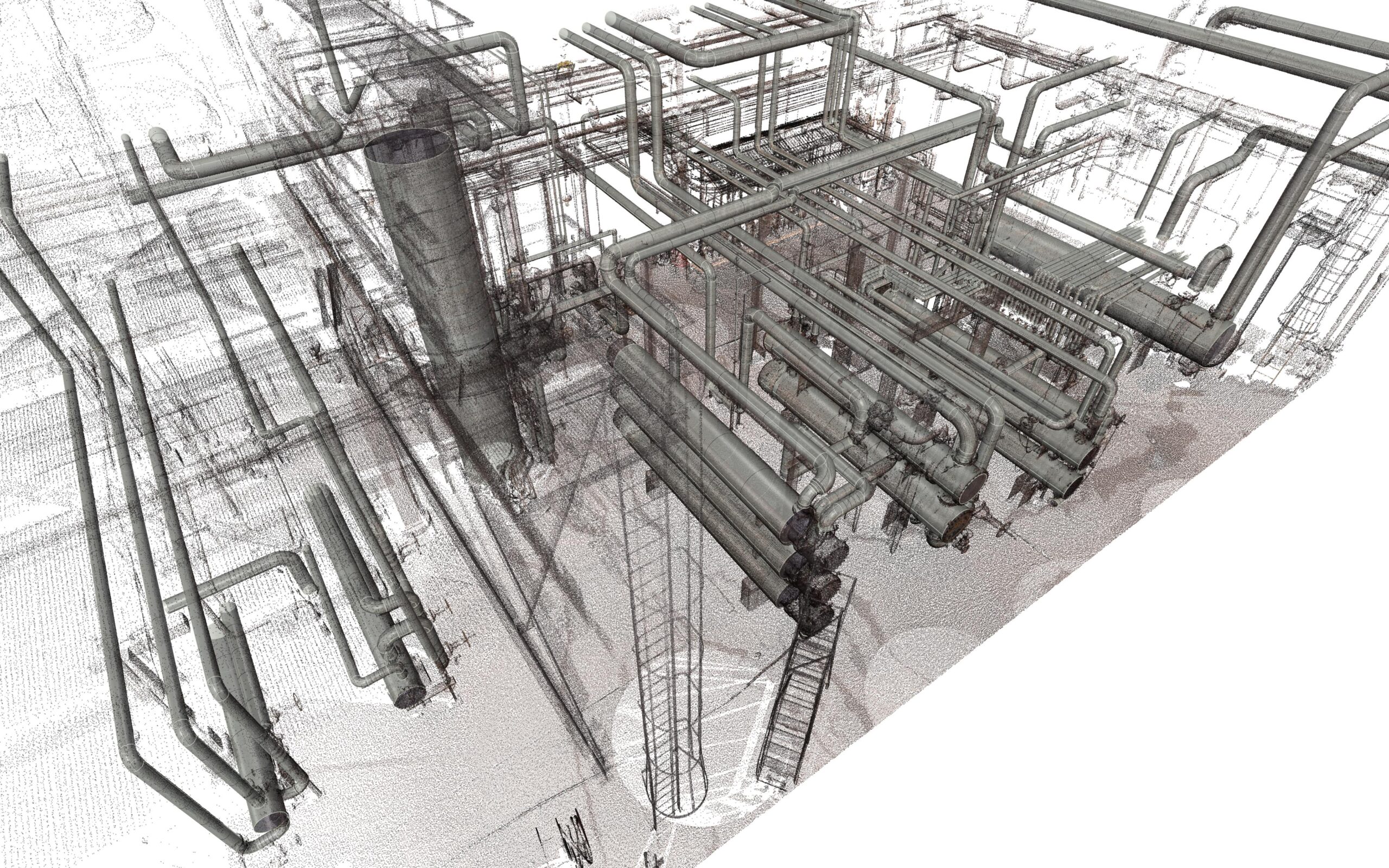

- Capture your scan data. Use your laser scanner to capture a comprehensive as-built record of your facility quickly, safely, and accurately.

- Use the defined reference points (targets) in your point cloud registration process to align your scan data with the plant control network (datum). This will also allow for accurate connection of future point cloud datasets.

Just five simple steps and a few extra minutes, and you can make sure your scan data is captured in a framework that will provide a solid foundation for your digital twin.

From there, you can confidently round-trip your data to a contractor for layout and verification of new installations and retrofits; use it for virtual walkthroughs for operations and maintenance; and continue to find new uses that add value.

Are you ready to bring your project workflow full circle? Contact one of our industry plant solutions consultants to learn more.

About the Author: