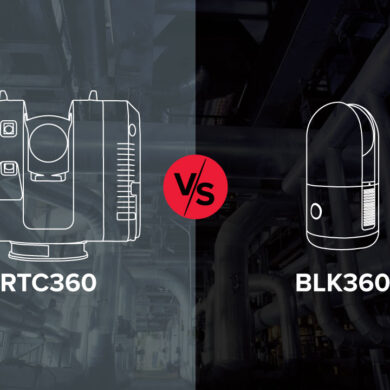

Which laser scanner is better? The answer might surprise you.

As plant managers strive to minimize downtime, every laser scanning job is a race against time. After all, time is money. Lost production can cost $100,000…

What do you need to know about establishing a plant coordinate system for your digital twin? Zachary McNeil of Proport Pipefitting offers some insights.

Think it costs too much to invest in laser scanning? Industrial plant solutions specialist Greg Schneider offers a different perspective.

Autonomous laser scanning technology integrated with robust and mobile robotic inspection systems provide new insight that provides a big impact on plant operations.

When precision and reliability are non-negotiable, technology matters. Travis Sachs, president and COO of 3DS Technologies, explains why the company relies on Leica Geosystems as a technology partner.

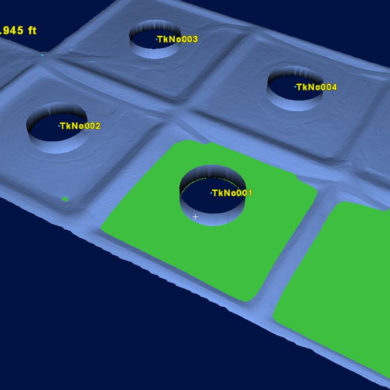

Using 3D laser scanning to capture existing conditions on secondary containment is a basic preventive measure.

Watch the video to see how 3D laser scanning makes accurate digital plant documentation fast, simple and safe.

Providing the best accuracy, quality, and service in 3D plant documentation requires the best technology. These key criteria reveal a clear winner.

If you’re still using traditional tank gauging, you may be putting your organization at risk. Read why 3D digital tank analysis is the best approach.