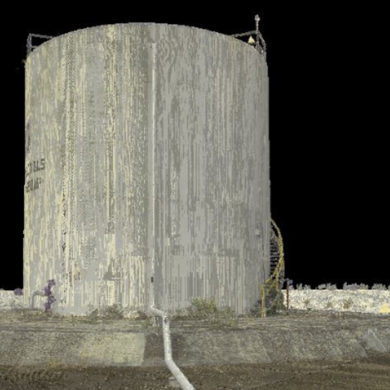

If you’re still using traditional tank gauging, you may be putting your organization at risk. Read why 3D digital tank analysis is the best approach.

Recent advances make 3D laser scanning the fastest, most accurate and safest way to capture comprehensive data.

A focus on quality and innovation drives decisions for this leading-edge laser scanning services firm.

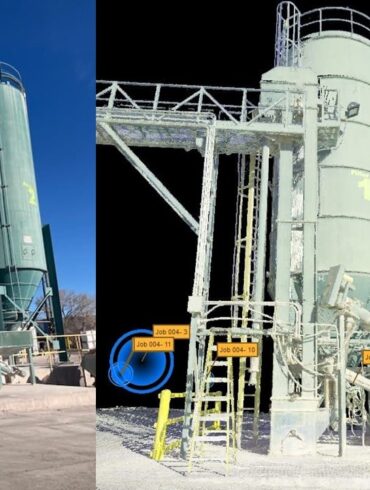

Autonomous laser scanning technology integrated with robust and mobile robotic inspection systems provide new insight that provides a big impact on plant operations.

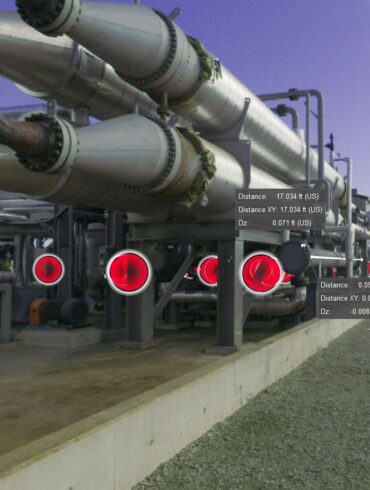

Providing the best accuracy, quality, and service in 3D plant documentation requires the best technology. These key criteria reveal a clear winner.

Industry veteran Frank Latz shares insights on accuracy, data use, and equipment recommendations.

“There is never any question that every project begins with scanning; the value that it adds to projects is evident.”

As plant managers strive to minimize downtime, every laser scanning job is a race against time. After all, time is money. Lost production can cost $100,000…

A combination of expertise and the right digital documentation technology provides clients with significant advantages in plant engineering...

The ability to quickly and accurately measure industrial plants provides cost savings and safety benefits.