Most executives across industry sectors believe in the benefits of a digital twin, but the business value can be difficult to quantify. A new study reveals the true potential and how to harness it.

What do you need to know about establishing a plant coordinate system for your digital twin? Zachary McNeil of Proport Pipefitting offers some insights.

Which laser scanner is better? The answer might surprise you.

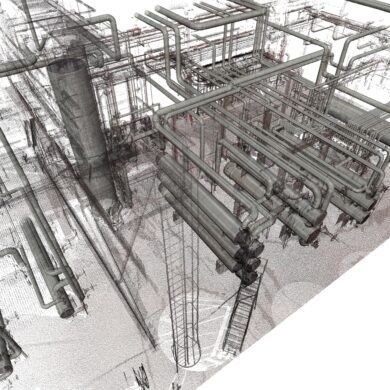

The ability to consistently provide fast-turnaround, high-quality results, even on complex projects, requires the right approach.

Think it costs too much to invest in laser scanning? Industrial plant solutions specialist Greg Schneider offers a different perspective.

Providing the best accuracy, quality, and service in 3D plant documentation requires the best technology. These key criteria reveal a clear winner.

Without a plant coordinate system to hold and align your scanning work, you risk inaccuracies, inconsistencies, and disconnected data sets that can prevent you from achieving a true digital twin.

Industry veteran Frank Latz shares insights on accuracy, data use, and equipment recommendations.

Is establishing an accurate plant coordinate system really as simple as it sounds? Here’s an overview of what’s involved and how you can benefit.

ESDC's Russell Whitehead explains the significant advantages of having a current digital twin of your entire plant.