If you haven’t yet been able to make the changes in your industrial plant that you know are needed, try starting with the data.

Download this white paper to learn how to establish 3D laser scanning as a standard way to reduce rework, cut costs and retool with confidence.

Rob Jickling of Element6 Solutions shares how reality capture can maximize efficiency, agility and safety in any plant environment.

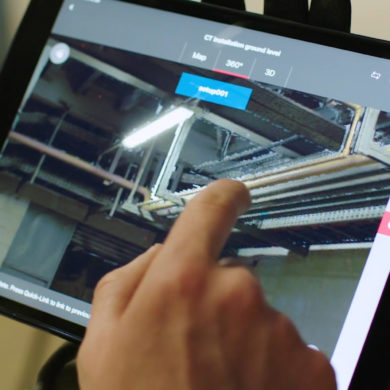

A digital replica of physical assets and processes is crucial to maximizing safety and fine-tuning your manufacturing processes. Get the PDF summary.

Travis Sachs, president of laser scanning service provider 3DS Technologies, discusses the transformative power of laser scanning in industrial settings in this Tech Insider interview.

A new on-demand webinar explores the end-to-end solution that will change the way you see laser scanning.

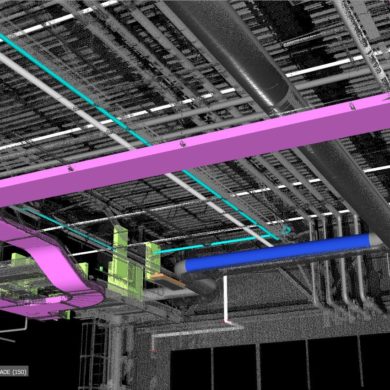

3D laser scanning is the most effective way to safely, quickly capture comprehensive and accurate measurements.

Industry veteran Frank Latz shares insights on accuracy, data use, and equipment recommendations.

Which laser scanner is better? The answer might surprise you.

Accurate reality capture helps Darling Geomatics streamline as-built and construction verification for a 1.5-million-sq-ft Mercedes-Benz facility expansion.