Cloud-based solutions empower you to access your plant remotely from any location so you can keep your business moving even when you can’t be there in person.

Which laser scanner is better? The answer might surprise you.

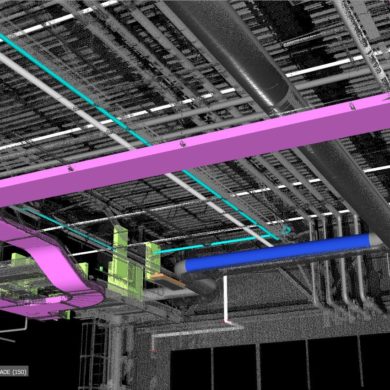

Without a plant coordinate system to hold and align your scanning work, you risk inaccuracies, inconsistencies, and disconnected data sets that can prevent you from achieving a true digital twin.

Providing the best accuracy, quality, and service in 3D plant documentation requires the best technology. These key criteria reveal a clear winner.

A new integration of Leica Geosystems’ RTC360 technology onto Boston Dynamics agile mobile robot Spot opens new possibilities for digital remote management.

As plant managers strive to minimize downtime, every laser scanning job is a race against time. After all, time is money. Lost production can cost $100,000…

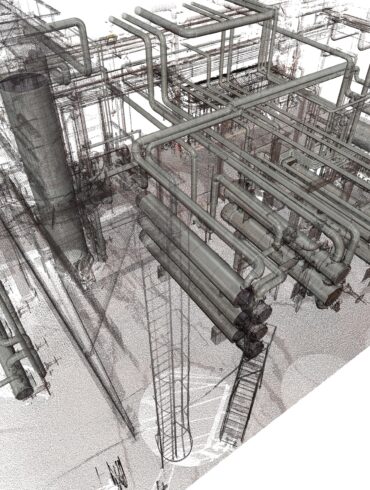

3D laser scanning is the most effective way to safely, quickly capture comprehensive and accurate measurements.

When Hurricane Katrina roared through the Gulf of Mexico in 2005, it took more than 1,200 lives and did billions of dollars in property damage...

Industry veteran Frank Latz shares insights on accuracy, data use, and equipment recommendations.

Is establishing an accurate plant coordinate system really as simple as it sounds? Here’s an overview of what’s involved and how you can benefit.